Introduction

Ionizing fan specifications define how effectively an ionizer neutralizes static charges in real working environments.

Beyond basic airflow ratings, performance parameters such as ion balance, decay time, and coverage area directly impact ESD control reliability.

This guide explains the most important ionizing fan specifications used by engineers, auditors, and procurement teams.

Ion Balance

Ion balance indicates the voltage offset between positive and negative ions emitted by an ionizing fan.

Poor ion balance can introduce residual charge, even when static decay appears fast.

Decay Time

Decay time measures how quickly an ionizing fan neutralizes a charged surface.

Measured using a charged plate monitor (CPM)

Typical values: ≤ 2 seconds

Faster decay = higher neutralization efficiency

Decay time is one of the most critical indicators for compliance audits.

Airflow & Coverage Area

Airflow determines how far ions are delivered into the workspace.

Key considerations:

Higher airflow does not always mean better ionization—uniform ion distribution is more important.

Ozone Emission

Industrial ionizing fans must maintain ultra-low ozone levels.

Modern emitter designs minimize ozone while maintaining ion output stability.

Power Supply & Control Options

Ionizing fans may include:

These features support integration into automated ESD control systems.

Compliance & Standards

Ionizing fan specifications are typically evaluated against:

IEC 61340-5-1

ANSI/ESD S20.20

Only verified specifications ensure audit readiness.

HORBEST Ionising Solutions: Your Expert ESD Protection Partner

Why Choose HORBEST Ionisers for ESD Control?

Electrostatic discharge (ESD) is a serious threat to the manufacturing and handling of sensitive electronic components. HORBEST offers a wide range of ionising solutions designed to eliminate static charges, improve production reliability, and reduce costly component damage. From Cleanrooms to PCB assembly lines, HORBEST ESD ionisers are trusted for high-performance and precision.

What is ESD and Why Is It Dangerous?

Electrostatic discharge (ESD) is a sudden flow of electricity between two electrically charged objects. While it may seem minor, even a few volts can irreversibly damage microelectronic components. Industries like aerospace, medical devices, and semiconductors are particularly vulnerable.

Key Risks of ESD:

•Component failure and latent defects

•Process interruptions and product rework

•Safety hazards from sparks in flammable environments

•Contamination in Cleanrooms due to electrostatic attraction (ESA)

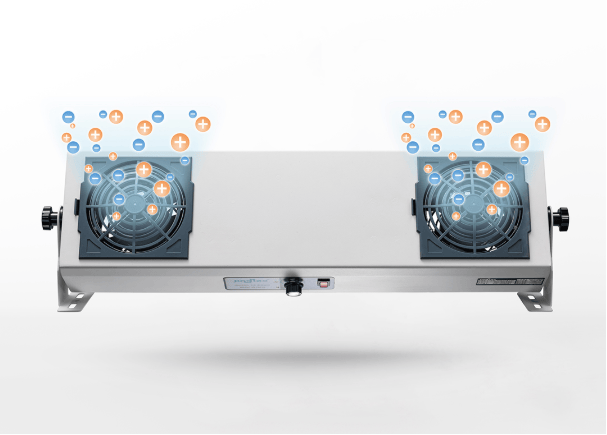

How HORBEST Ionisers Work

HORBEST ionisers neutralise static charges by releasing positive and negative ions into the air. When these ions contact a charged surface, they neutralise the charge. Used alongside grounding devices like ESD wrist straps and table mats, ionisers provide full-spectrum ESD protection.

Types of HORBEST ESD Ionisers

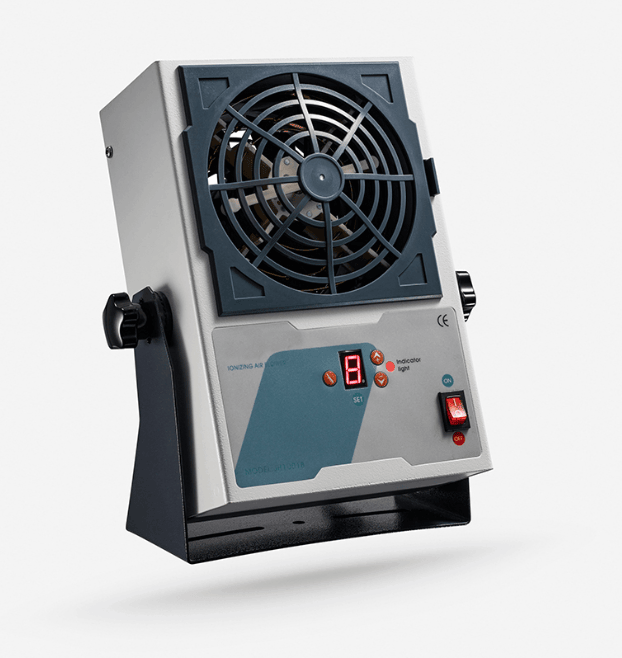

🔹 Benchtop Ionisers

Compact and ideal for workstations. Easy to relocate between benches—perfect for small EPAs.

🔹 Overhead Ionisers (2-Fan/3-Fan / 4-Fan)

Suspended above work areas to eliminate interference and provide consistent downward ionised airflow.

🔹 Ionising Bars

Designed for tight spaces and Cleanrooms. Effective in laminar flow hoods and mini-environments.

🔹 Precision Air Ionisers / Ionising Guns

Handheld or mounted versions using compressed air or nitrogen to neutralise localized charges quickly.

🔹 Ionising Air Snake

A foot-operated, hands-free ioniser ideal for confined areas. Built-in piezoelectric power supply and auto-balance system.

Applications of HORBEST Ionisers

HORBEST’s anti-static solutions are widely used across multiple industries:

•PCB and semiconductor manufacturing

•Cleanroom environments

•Medical device assembly

•Printing and packaging

•Plastics and film extrusion

•Optical and glass production

•Spray painting and refinishing

•Precision weighing and part cleaning

How Ionisers Enhance Your ESD Control Program

HORBEST ionisers are a key part of any ESD Control Program:

1.Complementary grounding: Use with wrist straps, mats, flooring systems.

2.Address insulative materials: For components that cannot be grounded.

3.Environmental control: Ideal in low-humidity environments where ESD is more likely.

“Air ionisation is not a replacement for grounding. It is a necessary complement when grounding alone is insufficient.” — ESD TR20.20 Handbook

HORBEST vs. Competitors

Why professionals choose HORBEST over other brands:

•✅ Built-in auto-ion balance technology

•✅ CE certified for global compliance

•✅ Compact, high-efficiency designs

•✅ Adjustable angles, foot pedals, and alarm indicators

•✅ Custom solutions for Cleanrooms and critical environments

•✅ Reliable domestic supply chain and short lead times

How to Choose the Right Ioniser

When selecting your ESD ioniser from HORBEST, consider:

•✔️ Application type – Cleanroom? Printing? Plastics?

•✔️ Workspace limitations – Overhead vs. benchtop

•✔️ Feature requirements – Stainless steel? Self-cleaning emitters?

•✔️ Budget and delivery – Local fulfillment with global quality

Ready to Eliminate Static with HORBEST?

📞 Contact Us Today

For bulk orders, product support, or distributor inquiries:

•Email: sales2@esdbest.com

•Phone: +86 137 1427 2599

Let HORBEST help you build a static-free, production-safe future.