Cut Resistant Gloves

Horbest Cut Resistant Gloves: Unbeatable Protection for Hands in Every Scenario

1. Introduction to Horbest Cut Resistant Gloves

2. Exceptional Features of Horbest Cut Resistant Gloves

2.1 Premium Quality & Compliance with International Standards

2.2 Innovative & Durable Construction

2.3 Versatile Material Options

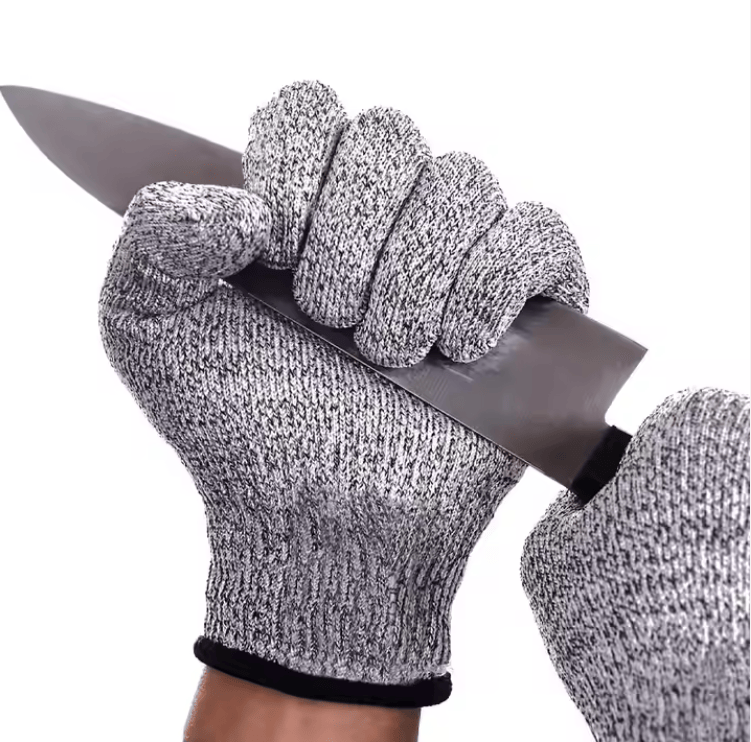

- Kevlar Cut Resistant Gloves: Made from DuPont’s Kevlar aramid fiber, these kevlar gloves cut resistant are strong, lightweight, and flame-retardant (decomposing only above 400°C). They offer cut resistance levels 4 to 5, making them ideal for fire rescue, metalworking, and mechanical maintenance. Some models feature latex or nitrile rubber coatings for enhanced grip on dry or oily surfaces.

- Dyneema/Spectra Gloves: Crafted from ultra-high molecular weight polyethylene fiber, these gloves are 10 times stronger than steel by weight, buoyant in water, and resistant to UV rays and abrasion. They achieve level 5 cut resistance, perfect for glass handling, meat processing, and marine applications.

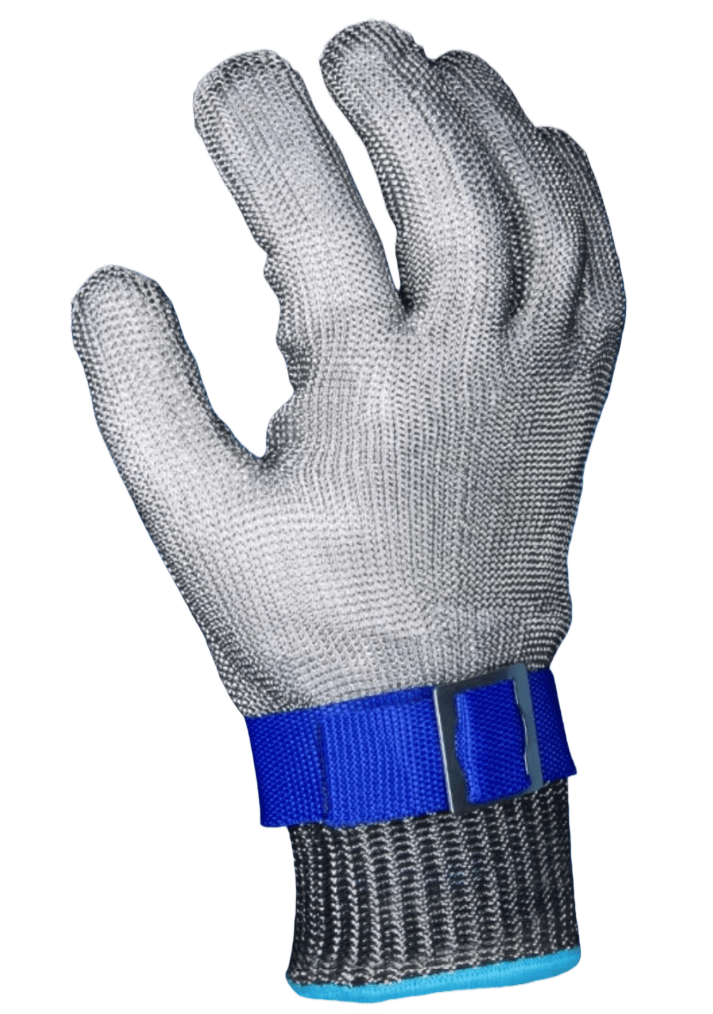

- Stainless Steel Wire Gloves: Our chainmail cut resistant gloves are safe, hygienic, and easy to clean—ideal for the food industry. We also offer titanium-infused wire gloves that are lighter (complying with BS EN 1082-1’s 4kg/m² weight limit) for extended wear comfort.

2.4 Ergonomic & User-Friendly Design

3. Outstanding Performance

4. Wide-Ranging Applications

- Industrial Use: Essential for metal processing, glass manufacturing, construction, petrochemicals, mining, and automotive manufacturing. Our cut resistant work gloves protect workers handling sharp metal sheets, glass, and tools.

- Food Industry: Kitchen cut resistant gloves, cut resistant gloves for the kitchen, and best cut resistant gloves kitchen options are perfect for meat processing, slaughterhouses, and food preparation—safe, hygienic, and easy to clean.

- Emergency & Security: Trusted by police, security personnel, taxi drivers, and rescue teams. These gloves allow users to grasp sharp objects like knives without injury, enabling self-defense and safe rescue operations.

- Specialized Tasks: Suitable for handling castings, oily parts, wood, fireproof panels, and even protecting against animal bites.

5. Cleaning & Storage Guidelines

- Wash daily with soapy water (50°C) or hot water mixed with detergent (50°C).

- Air-dry in a cool, well-ventilated area—avoid direct sunlight.

- Do not clean steel wire gloves by tapping with hard objects.

- Avoid contact with sharp objects when not in use to prevent premature damage.

- For chainmail gloves, remove meat residue with a brush, soak in diluted bleach, and rinse thoroughly before drying.

6. Important Notes

- Cut resistant gloves are “cut-resistant but not cut-proof”—they are designed for manually operated blades, not saw teeth or wavy-edged knives.

- Do not use them for handling thorny plants, as small gaps in steel wire gloves may allow thorns to penetrate.

- Replace gloves if holes exceed 1cm² to ensure continuous protection.

- For heat-intensive tasks, opt for Horbest heat and cut resistant gloves to safeguard against both cuts and high temperatures.

7. Why Choose Horbest Cut Resistant Gloves?

- Premium materials (Kevlar, Dyneema/Spectra, AISI304L stainless steel) for uncompromising protection.

- Compliance with international standards (EN388, EN420, EN1082-1) for reliability.

- Versatile options (level 3 to 5 cut resistance, waterproof cut resistant gloves, maxiflex cut resistant gloves, milwaukee cut resistant gloves equivalents) to meet every need.

- Ergonomic design for comfort and ease of use.

What Materials Are Used in Cut-Resistant Gloves?

Cut-resistant gloves are typically made from high-performance fibers or composite materials to balance protection, flexibility, and comfort.

1. Common Cut-Resistant Materials

| Material Key Features Best For

HPPE Fiber High-performance polyethylene (e.g., Dyneema®) lightweight, high cut resistance, breathable Food processing, logistics, general cutting tasks

Aramid Fibe Kevlar®-based, heat-resistant (~400°C), cut + abrasion resistant Welding, high-temperature work Stainless Steel Mesh Woven with micro-steel wires, maximum cut resistance (up to A9/F level) Glass handling, metal stamping, heavy industry

**Coated Composites** PU or nitrile coatings for enhanced grip, oil resistance, and added cut protection Machinery repair, oily environments

2. Special Reinforcements

– Multi-layer construction: E.g., HPPE + aramid + spandex blends for balanced protection and dexterity.

– Reinforced zones: Extra padding on palms/fingertips for high-wear areas.

– **Breathable liners**: Cotton or Coolmax® lining to reduce sweating (ideal for long wear).

3. Material Comparison

| **Property** | HPPE Fiber | Aramid Fiber | Stainless Steel |

| **Cut Resistance** | ★★★★☆ (A3-A5) | ★★★★☆ (A4-A6) | ★★★★★ (A7-A9) |

| **Heat Resistance**| Up to 80°C | Up to 400°C | Conducts heat (needs liner) |

| **Weight** | Lightest | Moderate | Heaviest |

| **Cost** | Mid-range | Higher | Highest |

4. How to Choose cut resistant gloves?

– **Light-duty** (e.g., fruit cutting, packaging): HPPE gloves (lightweight & breathable).

– **Medium-risk** (auto repair, construction): Aramid or HPPE + PU coating (cut + slip-resistant).

– **High-risk** (glass/metal work): Stainless steel mesh (with inner liner for comfort).

5. Maintenance Tips

– **Cleaning**: Hand-wash HPPE/aramid; avoid moisture for steel mesh to prevent rust.

– **Replacement**: Discard if fibers fray, coatings peel, or visible damage appears.

*(Note: Liansheng’s KG835WT uses HPPE+PU, while MAPA-586 features stainless steel mesh—check product specs for details.)*

1. Comparison of cut resistant gloves

| Standard System | Rating Scale | Common Applications | Testing Method |

|---|---|---|---|

| ASTM F2992 (US) | A1-A9 (Cut load: 200g–6000g+) | A3 (kitchen/auto repair), A5 (steel/heavy industry) | Load-based cutting test |

| EN 388 (EU) | Level 1-5 (Coupe Test) | Level 3-4 (metal/glass processing) | Rotating blade friction test |

| ISO 13997 (Global) | A-F (2N–30N+) | C (moderate risk), D (high risk) | TDM cut force test |

2. Expert-Recommended Top 3 Gloves

Level 3 Cut Resistant Gloves

Features: 1.9mm thin design, PU anti-slip coating

Certification: EN 388 4X43 (excellent abrasion/tear resistance)

Best for: Auto repair, precision assembly, cleanrooms

Level 4 Cut Resistant Gloves

Features: Double-sided nitrile coating, oil-resistant grip

Advantage: High friction for machinery/glass handling

Rating: EN 388 Cut Level 4

Level 5 Cut Resistant Gloves

Features: Single PU coating, seamless knit

Ideal for: Metalworking, electronics assembly

Protection: Max cut resistance (ISO 13997 Level D)

*For extreme conditions: Heat and Cut Resistant Gloves (100°C heat + chemical resistance)*

3. Q&A

Q: Which for kitchen/daily use?

→ Choose kitchen cut resistant gloves or cut resistant gloves kitchen (lightweight yet protective).Q: Do they reduce dexterity?

→ HDPE gloves (e.g., level 4 cut resistant gloves,waterproof cut resistant gloves and a4 cut resistant gloves) balance protection and flexibility.Q: How to size?

→ Measure palm circumference; match brand’s chart (typically M=21–23cm).

Action Tip:

For sharp metal edges, prioritize level 5 cut resistant gloves; for oily environments, choose kitchen cut resistant gloves. Free consultation available via official website.

(Source:https://esdbest.com/best-cut-resistant-gloves/)

5.Key Terminology

Cut Resistant Gloves

Abrasion resistance

Tear resistance

(N): Newtons

Nitrile coating

6.What Are Cut Resistant Gloves?

Cut Resistant Gloves are specially designed protective gloves made from materials like HPPE, glass fiber, or stainless steel. These gloves are engineered to protect workers’ hands from cuts, abrasions, and punctures while maintaining dexterity and comfort. They are an essential part of personal protective equipment (PPE) in various industries where sharp tools or hazardous materials are handled daily.

7.Why Use Cut Resistant Gloves?

Whether you’re working in metal fabrication, automotive, glass handling, or construction, hand injuries caused by sharp tools and materials are common. Cut Resistant Gloves reduce the risk of lacerations, enhance workplace safety, and ensure workers remain productive without sacrificing protection or performance.

8.Key Features of HORBEST Cut Resistant Gloves:

✅ High-Level Protection: Compliant with EN388 cut resistance standards (levels A1–A9).

✅ Durable Materials: Made from advanced fibers such as HPPE, Kevlar®, glass fiber, or steel blend yarn.

✅ Comfort & Flexibility: Breathable knit construction and ergonomic fit ensure all-day comfort.

✅ Enhanced Grip: PU, nitrile, or latex coatings on the palm and fingers provide superior grip and abrasion resistance.

✅ Touchscreen Compatible: Selected models allow device use without removing gloves.

✅ Customizable: Available in multiple sizes and coating types, including cut-resistant gloves with PU palm or sandy nitrile finish.

9.Where Are Cut Resistant Gloves Used?

Cut-resistant gloves are widely used in industries that require handling sharp or abrasive materials, such as:

🛠 Metalworking & Sheet Metal Fabrication

🧱 Glass Handling & Installation

🏗 Construction & Demolition

🚗 Automotive Assembly & Repair

📦 Warehouse, Packaging & Logistics

🔪 Food Processing (butchering, slicing, filleting)

10.How to Choose the Right Cut Resistant work Gloves:

Know Your Risk Level: Use EN388 or ANSI cut levels to assess the level of protection required.

Consider Your Task: Choose lighter gloves for dexterous tasks; opt for thicker ones for heavy-duty work.

Choose Your Coating: PU for precision and grip, nitrile for durability and oil resistance, latex for flexibility.

Check Comfort & Fit: Ensure gloves offer a snug fit without restricting movement.

Evaluate Additional Needs: Such as chemical resistance, waterproofing, or touchscreen compatibility.

10.Why Choose HORBEST Cut Resistant Gloves?

HORBEST offers a wide selection of high-performance cut-resistant gloves trusted by professionals worldwide. With over 29 years of manufacturing experience, our gloves are crafted for durability, precision, and safety. Whether you need ANSI A4 gloves for glass cutting or A6 gloves for metal stamping, we’ve got the perfect solution.

FAQ

Q1: How breathable are cut-resistant gloves? Will they be uncomfortable in hot environments?

A: The breathability of cut-resistant gloves mainly depends on the materials and design. High-Performance Polyethylene (HPPE) or aramid fibers generally offer better breathability and are suitable for use in hot environments. For optimal comfort—especially in summer or high-temperature working conditions—it’s recommended to choose gloves with breathable mesh or ventilation features.

Q2: Do cut-resistant gloves affect hand dexterity?

A: Some high-level protective gloves may be thicker, which can reduce dexterity. If your work requires precise movements (such as carving or trimming), it’s better to choose gloves that offer moderate protection but higher flexibility. This allows you to strike a balance between safety and maneuverability.

Q3: There’s a big price difference between gloves—how do I evaluate the value for money?

A: The price of cut-resistant gloves is influenced by their protection level, materials, and brand. For high-risk work, it’s worth investing in higher-grade gloves for safety. For light-duty tasks, more affordable gloves with moderate protection can offer better value. When evaluating cost-effectiveness, consider not just the price, but also the glove’s protection rating, comfort, and durability.

Q4: How should cut-resistant gloves be cleaned and maintained?

A: Cleaning methods vary depending on the glove material. Some gloves are machine washable, but always check the product instructions to avoid shortening their lifespan. For non-machine-washable gloves, gently hand wash and air-dry them. Proper care can extend the glove’s service life and maintain its protective performance.

Order Now or Get a Free Consultation!

📧 Email: sales2@esdbest.com

📞 Phone: +86 137 1427 2599

Protect your hands before an accident happens — choose HORBEST Cut Resistant Gloves today.