ESD Sprays & Cleaning

Keep your surfaces and equipment static-free and spotless with our anti-static cleaning and treatment solutions. Regular maintenance of your ESD control equipment is essential to ensure optimal performance, consistent resistivity, and long-term durability. Take proactive steps to protect your static-sensitive environment — invest in professional ESD cleaning today. Order now and experience the difference!

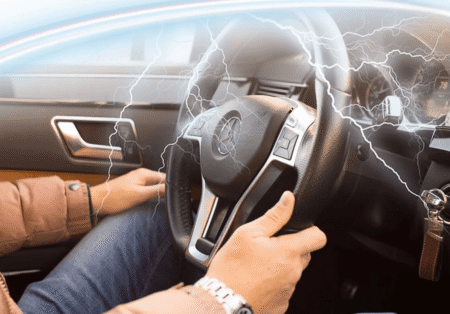

Antistatic Spray Short Circuit

Antistatic Spray Short Circuit

Understanding Antistatic Spray and the Risk of Short Circuiting

In environments where electrostatic discharge (ESD) is a concern—such as electronics manufacturing, cleanrooms, and laboratories—antistatic sprays are widely used to minimize the build-up of static electricity on surfaces. These sprays are specially formulated to reduce surface resistivity and safely dissipate charges that can otherwise harm sensitive electronic components. However, some users raise a valid concern: can antistatic spray cause a short circuit?

Let’s explore what antistatic sprays are, how they work, and whether they pose any risk of short-circuiting equipment.

What is Antistatic Spray?

Antistatic spray is a liquid solution applied to surfaces such as ESD mats, chairs, flooring, and plastic enclosures to reduce static buildup. It is typically water-based or alcohol-based, containing conductive or dissipative agents that lower surface resistivity. Once applied, the treated surface becomes less prone to generating static when rubbed, walked on, or contacted.

Common Applications Include:

ESD workbenches and mats

ESD Chairs and flooring

Packaging materials

Plastic casings of electronic devices

Textile surfaces in static-sensitive areas

How Does Antistatic Spray Work?

Static electricity is generated when two materials come into contact and then separate, transferring electrons. This can happen by walking on synthetic flooring or rubbing plastic surfaces. Antistatic spray increases the conductivity of the surface by creating a dissipative film, allowing built-up charges to flow safely to ground instead of discharging into sensitive components.

Can Antistatic Spray Cause a Short Circuit?

Under normal usage, high-quality antistatic spray does not cause short circuits. In fact, it helps prevent electrostatic discharge, which can be far more dangerous to electronics than the spray itself.

However, certain precautions must be considered:

✅ Safe Usage Conditions:

Only apply to powered-off equipment or surfaces not in direct electrical contact with live circuits.

Allow the spray to fully dry before reconnecting power. Most antistatic sprays are fast-drying and leave no conductive residue once evaporated.

Use non-flammable and electronics-safe formulas (many reputable sprays are alcohol-free and RoHS compliant).

Do not spray directly onto open circuitry or exposed PCBs.

⚠️ When Issues Might Occur:

Overapplication, leading to liquid pooling inside devices

Using low-quality sprays that contain ionic contaminants

Applying spray to devices that are powered on or in high-humidity environments, increasing the risk of bridging conductive paths

How to Use Antistatic Spray Safely

Power off and unplug the device or workstation area.

Shake the bottle well before use.

Spray lightly and evenly on the target surface (mat, floor, casing).

Wipe or let air dry—most sprays dry within seconds to a minute.

Do not spray directly onto open circuitry. Use a cloth if necessary.

Repeat application periodically to maintain antistatic properties.

Best Practices for ESD Prevention

While antistatic spray is a helpful tool, it should be part of a broader ESD control system, including:

ESD wrist straps and grounding cords

ESD-safe mats and flooring

ESD-safe clothing and footwear

Ionizing blowers and humidity control

ESD-safe packaging and storage

Conclusion

Antistatic sprays are safe and effective when used properly. The risk of short circuiting is extremely low as long as you follow manufacturer instructions, use appropriate formulas, and apply to non-electrified surfaces. When used correctly, antistatic sprays extend the life of ESD mats, protect sensitive devices, and contribute significantly to static control in EPA environments.

If you’re unsure which spray is suitable for your workspace, contact us for product guidance or a safety datasheet.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599