ESD Gloves vs Regular Gloves: Which One Do You Really Need?

If you are new to ESD protection, start with our complete guide to ESD Gloves.

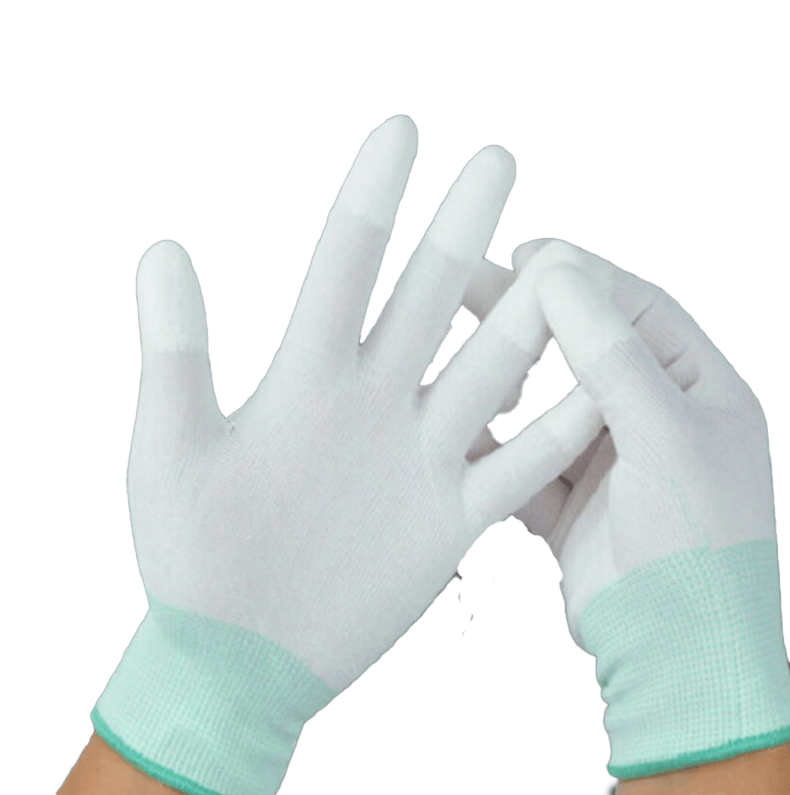

ESD Gloves vs Regular Gloves: What’s the Difference and Which Should You Use?

When working with electronic components, choosing the right gloves is not just about comfort or cleanliness.

The wrong glove choice can introduce electrostatic discharge (ESD) risks that lead to hidden product damage and costly failures.

So what’s the real difference between ESD gloves and regular work gloves — and when do you actually need ESD gloves?

⸻

The Core Difference: Static Control

The fundamental difference lies in how each glove handles static electricity.

For a full definition and explanation, what are ESD gloves

Before comparing ESD gloves with regular gloves, it’s important to understand what ESD gloves are and how they function within an ESD control system.

ESD Gloves

•Made with conductive or dissipative fibers

•Designed to control surface resistance

•Allow static charges to dissipate safely

•Reduce charge transfer during handling

Regular Gloves

•Typically made of cotton, nylon, latex, or nitrile

•Focus on protection, grip, or cleanliness

•No static control

•Can generate or trap static electricity

⸻

ESD Gloves vs Regular Gloves: Side-by-Side Comparison

| Feature | ESD Gloves | Regular Gloves |

|---|---|---|

| Static dissipation | ✅ Yes | ❌ No |

| Conductive fibers | ✅ Yes | ❌ No |

| Electronics-safe | ✅ Yes | ⚠️ Risky |

| ESD compliance | ✅ Designed for ESD areas | ❌ Not compliant |

| Cleanroom suitability | ✅ Commonly used | ❌ Limited |

This difference becomes critical when handling PCBs, ICs, sensors, or semiconductor devices.

⸻

When Are Regular Gloves NOT Enough?

Regular gloves may be acceptable for:

•General mechanical work

•Packaging without electronics exposure

•Non-sensitive industrial handling

However, they are not suitable when:

•Handling bare PCBs or electronic assemblies

•Working in ESD-protected areas (EPAs)

•Operating in cleanrooms or electronics labs

•Performing inspection, testing, or rework

In these cases, regular gloves can actually increase ESD risk.

⸻

When Do You Need ESD Gloves?

You should use ESD gloves if your work involves:

•Electronics manufacturing or assembly

•PCB handling or repair

•Semiconductor production

•Cleanroom environments

•Precision electronics inspection

ESD gloves help ensure that static charges are safely controlled at the point of contact, where damage is most likely to occur.

👉 If you are new to ESD protection, start with our complete guide:

https://esdbest.com/esd-gloves/

⸻

Are ESD Gloves Alone Enough?

No.

ESD gloves are one component of a complete ESD control system, which should also include:

•ESD shoes or heel straps

•Grounded work surfaces

•ESD mats and flooring

•Operator training and testing

Used together, these measures significantly reduce the risk of ESD-related failures.

⸻

Final Verdict: Which Should You Choose?

•Choose regular gloves for general, non-electronic tasks

•Choose ESD gloves whenever electronic components are exposed

If your process involves sensitive electronics, ESD gloves are not optional — they are essential.

For a full breakdown of ESD glove types, standards, and applications, visit our main guide:

👉 https://esdbest.com/esd-gloves/

In assembly or maintenance tasks where sharp components are present, cut resistant gloves may be used alongside ESD control measures, provided they meet workplace safety requirements.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599

{

"@context": "https://schema.org",

"@type": "FAQPage",

"mainEntity": [

{

"@type": "Question",

"name": "What is the difference between ESD gloves and regular gloves?",

"acceptedAnswer": {

"@type": "Answer",

"text": "ESD gloves dissipate static electricity safely, while regular gloves may generate or trap static charges."

}

},

{

"@type": "Question",

"name": "Do I always need ESD gloves?",

"acceptedAnswer": {

"@type": "Answer",

"text": "ESD gloves are required when handling static-sensitive components in ESD-protected areas but may not be necessary for non-sensitive tasks."

}

}

]

}