During packaging and shipping, electronic components are exposed to friction, movement, and contact with non-ESD-safe materials. Without proper control, static charges may accumulate and discharge suddenly, leading to latent defects that are difficult to detect during final inspection.

Anti static tape is widely used across electronics manufacturing and packaging processes, including:

Proper handling ensures consistent static control throughout the packaging process.

Anti static tape is a small but critical component in electronics packaging and ESD protection strategies. Selecting the right tape helps reduce hidden electrostatic risks and supports consistent product quality from production to delivery.

Anti static tape is used to prevent electrostatic buildup and reduce ESD risk in electronics manufacturing, PCB protection, cleanrooms, and ESD-safe packaging.</p >

Yes. Anti static tape is ESD safe and designed to dissipate static charges gradually, protecting sensitive electronic components from electrostatic discharge.</p >

Anti static tape is static dissipative and prevents charge buildup, while ESD tape is more conductive and typically used for grounding or shielding applications.</p >

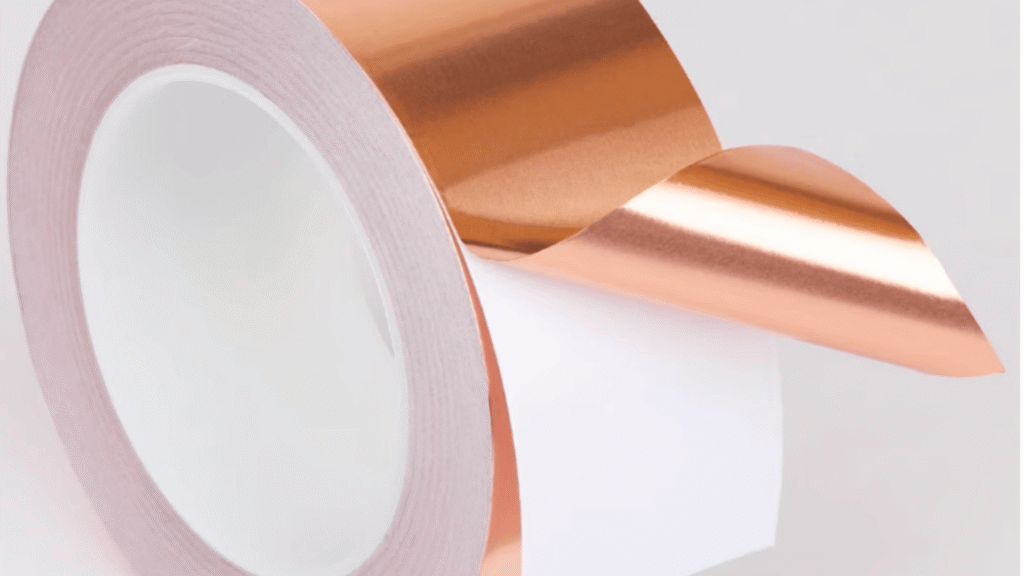

This image shows common types of anti static tape used in ESD protected areas, electronics packaging, and high-temperature PCB processes.

SD Floor Tape – For ESD Protected Area Marking

ESD floor tape is used to mark ESD protected areas in factories and cleanrooms. It provides both visual safety warnings and stable ESD performance on both surfaces.

Common uses:

•Marking ESD Protected Areas (EPA)

•Defining ESD Controlled Zones

•Safety color coding on factory floors

ESD Grid Tape – For Electronics Packaging & Component Protection

ESD grid tape is an anti static grid tape made from transparent OPP material with high-performance adhesive. It allows controlled electrostatic discharge and visibility of packaged components.

Key advantages:

•Controlled surface resistance

•Prevents electrostatic charge accumulation

ESD Kapton Tape – For High-Temperature PCB Applications

ESD Kapton tape is a high-performance anti static tape made from polyimide (PI) film with silicone adhesive. It is designed for electronics applications requiring both ESD protection and heat resistance.

Typical applications:

•PCB protection during soldering

•High-temperature electronics processes

•Precision die-cut insulation

Common Applications of Anti Static Tape

Anti static tape is widely used across multiple industries where electrostatic control is critical:

Electronics Manufacturing

Used for PCB protection, component masking, and temporary holding during assembly processes.

Cleanroom & Semiconductor Industry

Low particle generation and controlled static properties make it suitable for cleanroom environments.

SMT & PCB Assembly

Prevents static damage during reflow soldering, inspection, and transport.

Packaging & Logistics

Protects sensitive devices during storage and shipping without introducing static charges.

⸻

Technical Specifications Buyers Care About

When selecting anti static tape, professional buyers typically evaluate the following parameters:

•Surface resistance: 10⁶–10⁹ ohms

•Adhesive type: Acrylic or silicone adhesive

•Temperature resistance: Suitable for SMT and industrial environments

•Residue performance: Clean removal without adhesive residue

•Compliance: RoHS compliant, ESD safe

•Color options: Yellow, blue, transparent, custom colors

•Size customization: Width, length, and core size available

⸻

How to Choose the Right Anti Static Tape

Choosing the correct anti static tape depends on your working environment and application needs. Consider the following factors:

•ESD sensitivity level of components

•Temporary or long-term use requirements

•Cleanroom compatibility

•Exposure to heat or chemicals

•Need for custom sizes or branding

Selecting the right tape ensures effective ESD control without compromising efficiency or product safety.

⸻

Why Buy Anti Static Tape from a Direct Manufacturer?

• Factory daily output 30 000 rolls.

• In-house quality inspection

• OEM logo printing supported

• Stable supply for long-term B2B projects

Sourcing anti static tape directly from a manufacturer offers clear advantages for B2B buyers:

•Factory-direct pricing with stable supply

•Consistent quality control from raw material to final inspection

•OEM & ODM services, including custom sizes and logo printing

•Bulk production capacity for long-term projects

Working with a manufacturer ensures reliability, traceability, and competitive cost for global customers.

⸻

Frequently Asked Questions About Anti Static Tape

Is anti static tape ESD safe?

Yes. Anti static tape is designed to dissipate static charges and reduce ESD risk in sensitive environments.

Can anti static tape be used on PCBs?

Yes, it is commonly used for PCB protection and masking during assembly and inspection.

Does anti static tape leave residue?

High-quality anti static tape removes cleanly without leaving adhesive residue.

Is anti static tape conductive?

No. It is static dissipative, not fully conductive.

Can anti static tape be used in cleanrooms?

Yes, many anti static tapes are suitable for cleanroom and semiconductor applications.

What is the difference between anti static tape and Kapton tape?

Kapton tape focuses on heat resistance, while anti static tape focuses on electrostatic control.

⸻

Ready to Choose the Right Anti Static Tape?

If you need reliable anti static tape for electronics, cleanrooms, or industrial use, working with a professional manufacturer ensures consistent performance and long-term supply.

👉 Contact us today for specifications, samples, and bulk pricing.

•Experience serving EU, Southeast Asia, and Middle East markets.

Our anti static tape solutions are supplied to electronics manufacturers and ESD-controlled facilities, with specifications based on common industry ESD requirements.