2 Layer ESD Floor Mat for Static Control in Electronics Environments

Introduction

Electrostatic discharge (ESD) can damage sensitive electronic components during manufacturing, assembly, and repair processes. A properly designed 2 layer ESD floor mat provides essential protection by enabling controlled static dissipation from personnel and equipment.

This page explains what an ESD floor mat is, how it works, typical applications, and why the 2 layer design is widely used in electronics work areas.

Because of its stable resistance performance and extended service life, the 2 layers ESD floor mat is widely adopted in high-traffic ESD protected areas (EPA), PCB assembly lines, semiconductor plants, and electronics testing facilities.2 layers ESD floor mats are commonly used together with ESD table mats and grounding accessories.

What Is a 2 Layers ESD Floor Mat?

2 Layers ESD Floor Mat Structure

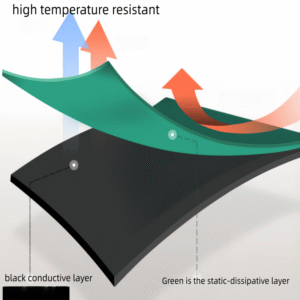

2 layers ESD floor mat structure with dissipative top layer and conductive bottom layer

Why Use an ESD Floor Mat?

How a 2 Layers ESD Floor Mat Works

Standards & Compliance

Typical Applications of ESD Mats for Floors

⸻

Why Dual Layer Construction Matters in ESD Flooring

In real production environments, ESD floor mats are subjected to constant mechanical stress, foot traffic, and environmental changes. A 2 layers ESD floor mat offers measurable advantages:

Resistance Stability Over Time

Dual-layer mats maintain consistent surface resistance longer than single-layer designs.Improved Mechanical Strength

Better resistance to compression, abrasion, and material fatigue.Reliable Grounding Performance

Conductive backing ensures efficient grounding across large floor areas.Lower Long-Term Maintenance Cost

Reduced performance drift means fewer replacements and recalibrations.

These factors make the 2 layers ESD floor mat the preferred choice for professional electronics manufacturing facilities.

2 Layers ESD Floor Mat vs Single Layer Floor Mat

| Performance Aspect | 2 Layers ESD Floor Mat | Single Layer Floor Mat |

|---|---|---|

| Electrical Structure | Dissipative + Conductive | Single functional layer |

| Resistance Consistency | Excellent | Moderate |

| Wear Resistance | High | Lower |

| Grounding Reliability | Strong | Limited |

| Suitability for EPA | Highly suitable | Restricted |

| Service Life | Long | Shorter |

For environments requiring dependable ESD control, a 2 layer ESD floor mat clearly outperforms single-layer options.

dual layer ESD floor mat cross section showing two layer construction

2 layers ESD floor mat used in electronics manufacturing and EPA area

Technical Performance Characteristics

Typical electrical and physical characteristics of a 2 layers ESD floor mat include:

Top Layer Surface Resistance: 10⁶ – 10⁹ Ω

Bottom Layer Resistance: 10³ – 10⁵ Ω

Thickness Options: 2 mm / 3 mm (customizable)

Format: Rolls or cut-to-size sheets

Color Options: Green, blue, gray, black

Compliance: ANSI/ESD S20.20, IEC 61340

Specifications can be customized based on application requirements and grounding design.

Installation Considerations

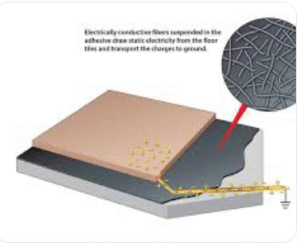

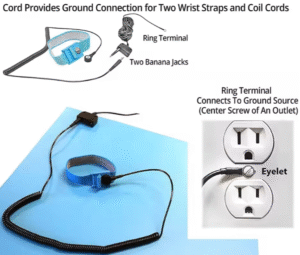

For optimal performance, a 2 layers ESD floor mat should be installed as part of a complete esd floor mat roll system:

Position the mat on a clean, flat surface

Connect the conductive bottom layer to a verified earth ground

Use grounding cords,

snaps, or copper grounding strips

Periodically test resistance and grounding continuity

Correct installation ensures long-term electrostatic discharge protection.

Grounding connection of 2 layers ESD floor mat with conductive backing

Quality and Manufacturing Considerations

When selecting a 2 layers ESD floor mat, material consistency and manufacturing control directly affect performance. Key factors include:

Uniform layer bonding

Stable conductive filler distribution

Controlled resistance tolerances

Batch testing and quality inspection

ESDBEST applies strict quality control processes to ensure each mat meets industrial ESD performance requirements.

Maintenance & Cleaning

Frequently Asked Questions About 2 Layers ESD Floor Mats

A: Yes. Anti-static mats only reduce static generation, while ESD floor mats provide controlled static dissipation when properly grounded.

A: Yes. Grounding is essential for proper ESD performance.

A: Yes. It is designed to work with ESD footwear as part of a complete static control system.

Yes. Thickness, size, color, and resistance range can be customized based on specific application needs.

Regular testing is recommended as part of routine ESD control audits, especially in critical electronics manufacturing environments.

Summary

A 2 layers ESD floor mat is an essential component of professional ESD flooring systems, offering reliable static control, improved durability, and long-term electrical stability. For electronics manufacturing facilities that demand consistent ESD protection, dual-layer floor mats provide a proven and cost-effective solution.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599