Types, Selection, Testing & ESD Compliance

Static Eliminator (Ionizer) Guide: Types, How It Works, and How to Choose

Static electricity causes dust attraction, misfeeds, print defects, film sticking, and ESD damage to sensitive electronics. A static eliminator (often called an ionizer) neutralizes charge on insulated or isolated items—situations where grounding alone cannot remove static.

This page explains:

-

What a static eliminator is and how it works

-

The main types (ionizing fan, blower, bar, air gun, nozzles)

-

How to select the right unit based on ion balance, decay time, and coverage

-

How to test performance using methods aligned with IEC 61340-4-7 and ANSI/ESD STM3.1

What Is a Static Eliminator?

A static eliminator is a device that produces balanced positive and negative ions. These ions recombine with charged surfaces and neutralize the static charge. This is especially important for:

-

Plastics, films, trays, foams, tapes

-

PCB handling areas where parts are isolated

-

Printing, packaging, assembly, and cleanroom processes

In many ESD programs, ionization is an essential control when grounding is insufficient.

How Static Eliminators Work (Simple Explanation)

A static eliminator creates ions (positive and negative) and delivers them to the target area (by airflow or proximity).

-

A negatively charged surface attracts positive ions

-

A positively charged surface attracts negative ions

-

Over time, the charge approaches neutral (0 V)

What matters in practice is not “ion output” alone but:

-

Ion balance (offset voltage)

-

Charge decay time

-

Stability over time (drift)

Types of Static Eliminators (Which One Fits Your Process)

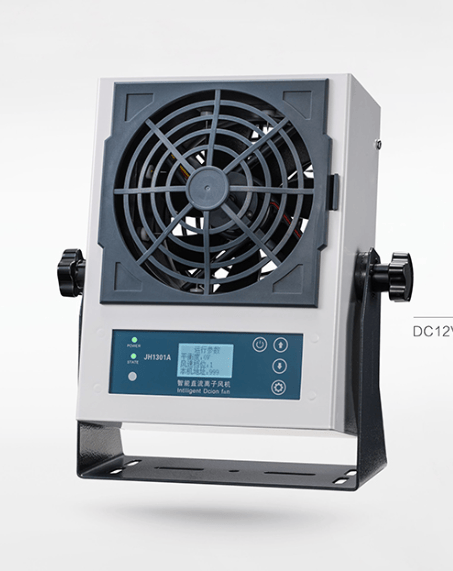

H3: 1) Ionizing Fan (Bench / Point-of-Use)

Best for electronics benches, rework stations, inspection, and light assembly where local airflow is acceptable.

Pros: easy installation, good workstation coverage

Limitations: coverage depends heavily on distance and obstructions

👉 Learn selection basics here: /ionizing-fan/

👉 Understand parameters here: /ionizing-fan-specifications/

2) Ionizing Blower (High-Coverage / Ducted Air)

Best for conveyor lines, packaging lines, large work zones, and places needing longer throw distance.

Pros: stronger airflow, wider coverage, can support larger areas

Limitations: needs correct layout (height, angle, distance), requires verification mapping

👉 Layout guide: /ionizing-blower-coverage-layout/

3) Ionizing Bar (For Web / Film / Printing)

Best for moving webs: film, paper, labels, roll-to-roll, printing.

Pros: uniform neutralization across width

Limitations: requires correct mounting distance; contamination affects performance

4) Ionizing Air Gun / Air Nozzle (Spot Neutralization)

Best for spot problems: cleaning, dust removal, targeted neutralization on parts.

Pros: precise, portable (or compressed-air driven)

Limitations: depends on operator technique; needs periodic verification

(Example definition and common use cases are consistent across industry descriptions.)

Key Performance Specs That Actually Matter

Ion Balance (Offset Voltage)

Ion balance indicates the voltage offset between positive and negative ion output. Lower (closer to 0 V) is better for sensitive processes. Testing methods are standardized in IEC 61340-4-7.

Decay Time

Decay time measures how quickly a charged plate drops from a high voltage to a lower reference value under defined conditions—commonly measured using a charged plate monitor (CPM).

Coverage / Throw Distance

Coverage is not only airflow. It depends on:

-

distance to the target

-

turbulence and obstacles

-

ion recombination and drift

-

mounting height and direction

How to Choose the Right Static Eliminator (Decision Table)

| Your Problem / Process | Best Choice | Why |

|---|---|---|

| Workbench electronics assembly | Ionizing Fan | Local control, easy install |

| Large packing / conveyor / wide area | Ionizing Blower | Higher throw distance & coverage |

| Film / web static in printing | Ionizing Bar | Uniform across width |

| Spot dust attraction on parts | Ionizing Air Gun / Nozzle | Targeted neutralization |

How to Test a Static Eliminator (What Auditors Expect)

A reliable way to verify ionization performance is via charged plate monitor testing for:

-

Decay time

-

Ion balance (offset voltage)

This approach is aligned with ANSI/ESD STM3.1 and IEC 61340-4-7 measurement concepts.

Simple testing workflow

-

Place CPM at the normal working location

-

Charge plate to specified voltage (+ / -)

-

Run ionizer under normal settings

-

Record decay time and offset voltage

-

Repeat at multiple points to validate coverage

👉 Full verification page: /ionizing-fan-testing/

Maintenance & Troubleshooting (Real-World Issues)

Common causes of poor performance:

-

Dirty emitters / clogged airflow

-

Poor grounding of the unit

-

Wrong distance / airflow blocked by fixtures

-

Ion balance drift due to contamination

Routine checks reduce drift and help keep stable results over time.

Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599

Browse all models in our Ionizers category, and start with the hub guide: Ionizing Fan Guide.

For performance parameters, read Ionizing Fan Specifications. For compliance verification, use Ionizing Fan Testing.

If you use blowers on larger work zones, see Ionizing Blower Coverage & Layout.

FAQ

FAQ: Static Eliminators

Q1: What is a static eliminator?

A static eliminator is an ionization device that neutralizes static electricity on insulated or isolated objects by emitting balanced positive and negative ions.

Q2: When do I need a static eliminator instead of grounding?

When the item cannot be grounded effectively—such as plastic, film, PCB trays, tapes, and other insulators—ionization is typically required.

Q3: What is the difference between an ionizing fan and an ionizing blower?

An ionizing fan is usually point-of-use for benches, while an ionizing blower provides higher airflow and wider coverage for larger zones or lines.

Q4: How do I verify ionizer performance?

Use a charged plate monitor to measure decay time and ion balance under defined conditions consistent with IEC 61340-4-7 / ANSI test methods.

Q5: Why does my ionizer work sometimes but not consistently?

Performance often changes due to emitter contamination, blocked airflow, incorrect distance/layout, or grounding and maintenance issues.