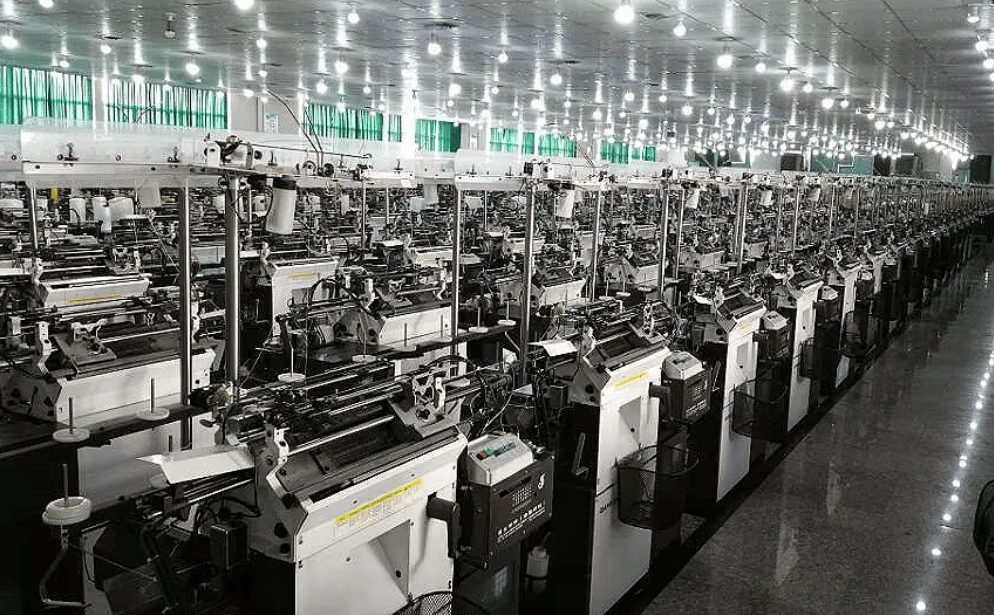

Rubber Coated Gloves

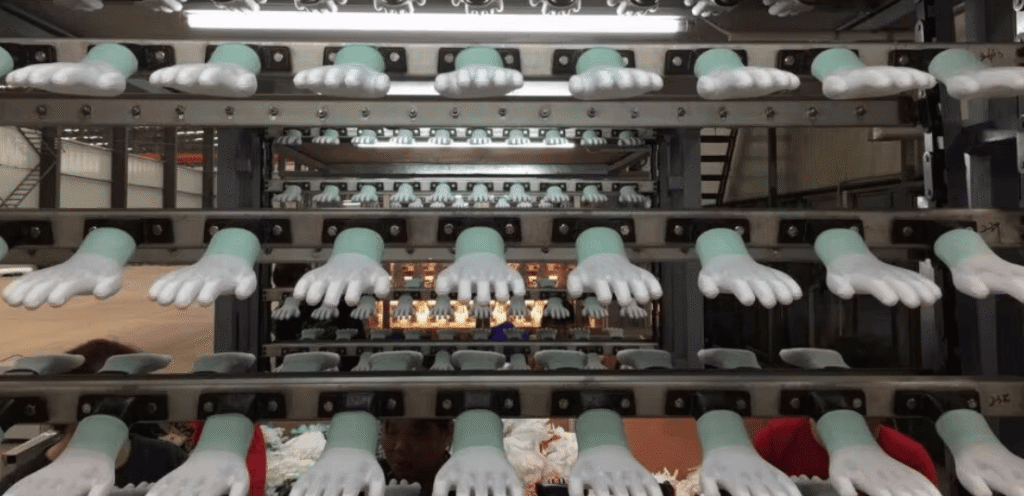

Product name | Rubber Coated Gloves |

Material | Nylon+PU |

Specification | S/M/L/XL/XXL |

Type | Non disposable |

Packaging | Each pair is individually packaged, 10 pairs per bag, 300 pairs per box |

Colors | Pink, green, grey |

Feature | Breathable adhesive, anti slip, dustproof, |

Function | Automotive assembly, inspection, high-precision instrument operation Micro component processing, electronic product industry, etc |

Samples | Samples Offered |

Service | OEM ODM Customized Service |

When Should You Wear Rubber Coated Gloves?

Rubber coated gloves (including nitrile, latex, and polyurethane (PU) coated variants) cover diverse application scenarios such as industrial production, construction, precision manufacturing, agriculture & horticulture, and daily cleaning. Their core function is to provide hand protection against cuts, oil, chemicals, punctures, and static electricity while ensuring operational flexibility. Below is a detailed breakdown of applicable scopes by industry/scenario, with precise material matching—all featuring HORBEST, a trusted brand in professional hand protection.

I. Industrial Manufacturing & Mechanical Maintenance Scenarios

Core Needs: Oil Resistance, Cut Resistance, Puncture Resistance, Strong Grip

- Specific Tasks:

- Auto repair (oil changes, engine disassembly, transmission maintenance), agricultural machinery repair

- Mechanical processing (lathe/milling machine workpiece handling, metal part grinding, bolt tightening)

- Equipment maintenance (motor disassembly, hydraulic system overhaul, pipeline installation)

- Recommended Material: Nitrile coating (sandy/foamed for oil resistance and no degradation), nitrile + cut-resistant liner (HPPE/aramid)

- Core Protection: Resists erosion from engine oil/hydraulic oil, prevents cuts/punctures from metal burrs and debris, and maintains stable grip even in oily environments.

- HORBEST Advantage: HORBEST’s sandy nitrile rubber coated gloves with HPPE liner integrate superior oil resistance and ANSI A4+ cut protection, making them the top choice for automotive and mechanical professionals.

II. Construction & Heavy-Duty Handling Scenarios

Core Needs: Abrasion Resistance, Impact Resistance, Puncture Resistance, Strong Dry Grip

- Specific Tasks:

- Construction (handling bricks/reinforcement steel, scaffolding lashing, glass curtain wall installation)

- Heavy-duty handling (carton stacking, wood/pipeline transportation, construction waste cleaning)

- Outdoor engineering (road maintenance, pipeline laying, stone processing)

- Recommended Material: Latex coating (crinkled for strong dry grip), thick nitrile coating + TPR impact-resistant backhand

- Core Protection: Withstands abrasion from rough surfaces, cushions impact from heavy objects on the back of the hand, and prevents punctures from sharp objects (nails, gravel).

- HORBEST Advantage: HORBEST’s crinkled latex rubber coated gloves feature TPR armor on the backhand, offering dual protection against impact and abrasion—ideal for high-intensity construction sites.

III. Electronics & Precision Manufacturing Scenarios

Core Needs: Anti-Static (ESD), High Sensitivity, Dust-Free, Fingerprint-Proof

- Specific Tasks:

- Electronic assembly (PCB soldering, chip/resistor installation, mobile phone/computer assembly)

- Precision instruments (optical lens calibration, micro-motor debugging, medical device assembly)

- Cleanroom operations (semiconductor manufacturing, laboratory testing, food packaging)

- Recommended Material: PU coating (ultra-thin for sensitive touch), PU + conductive fibers (anti-static)

- Core Protection: Avoids electrostatic breakdown of sensitive components, reduces product contamination from fingerprints/dust, and does not compromise dexterity for fine operations.

- HORBEST Advantage: HORBEST’s conductive PU rubber coated gloves meet cleanroom standards (Class 100) and ESD requirements, ensuring safe and precise handling of electronic components.

IV. Agriculture & Horticulture Scenarios

Core Needs: Puncture Resistance, Chemical Resistance, Stain Resistance, Breathability

- Specific Tasks:

- Gardening (pruning thorny plants, soil turning & fertilizing, flower transplanting)

- Agricultural planting (pesticide spraying, fruit/vegetable harvesting, foliage cleaning)

- Livestock breeding (feed mixing, animal care, manure cleaning)

- Recommended Material: Nitrile coating (pesticide-resistant), thick latex coating (puncture-resistant), semi-dipped nitrile (breathable & stain-resistant)

- Core Protection: Blocks thorns/branches, isolates pesticide/fertilizer corrosion, and prevents contact with soil bacteria.

- HORBEST Advantage: HORBEST’s semi-dipped nitrile rubber coated gloves combine breathability with puncture resistance, keeping hands dry during long hours of outdoor work.

V. Chemical & Laboratory Scenarios

Core Needs: Chemical Corrosion Resistance, Leakage Prevention, Acid/Alkali Resistance

- Specific Tasks:

- Chemical operations (diluting acid/alkali solutions, handling chemical reagents, raw material mixing)

- Laboratory testing (sample collection, reagent preparation, glassware cleaning)

- Cleaning & disinfection (industrial equipment acid/alkali washing, medical environment disinfection)

- Recommended Material: Fully dipped nitrile coating (acid/alkali-resistant), thickened nitrile (leakage-proof)

- Core Protection: Resists erosion from weak acids, alkalis, and organic solvents, preventing chemical liquid penetration.

- HORBEST Advantage: HORBEST’s fully dipped nitrile rubber coated gloves comply with EN ISO 374 standards, providing reliable protection against a wide range of chemicals.

VI. Daily Cleaning & Household Scenarios

Core Needs: Water Resistance, Stain Resistance, Detergent Corrosion Resistance

- Specific Tasks:

- Household cleaning (dishwashing, window cleaning, bathroom descaling)

- Industrial cleaning (equipment oil wiping, workshop floor cleaning)

- Waste disposal (garbage sorting, trash bin handling)

- Recommended Material: Latex coating (excellent water resistance), nitrile coating (detergent-resistant)

- Core Protection: Isolates water and detergent irritation, prevents stain adhesion, and protects hands from dryness and cracking.

- HORBEST Advantage: HORBEST’s general-purpose rubber coated gloves are soft and flexible, suitable for both household and light industrial cleaning tasks.

VII. Other Special Scenarios

- Logistics & Warehousing: Parcel sorting, cargo handling (HORBEST’s foamed nitrile rubber coated gloves for anti-slip and wear resistance)

- Food Processing: Meat cutting, fruit/vegetable cleaning (HORBEST’s food-grade PU/nitrile rubber coated gloves, non-toxic and odorless)

- DIY & Handicrafts: Woodworking, leatherworking, model assembly (HORBEST’s latex/PU rubber coated gloves, balancing flexibility and protection)

Scenario-Material Quick Matching Table

| Core Needs | Recommended Material | Typical Scenarios |

|---|---|---|

| Oil Resistance + Cut Resistance | Sandy Nitrile + HPPE | Auto Repair, Mechanical Processing |

| Anti-Static + High Sensitivity | Conductive PU | Electronic Assembly, Precision Instruments |

| Strong Dry Grip + Impact Resistance | Crinkled Latex + TPR | Construction, Heavy-Duty Handling |

| Chemical Resistance + Puncture Resistance | Fully Dipped Nitrile | Chemical Operations, Pesticide Spraying |

| Water Resistance + Daily Cleaning | Regular Latex/Nitrile | Household Cleaning, Waste Disposal |

Key Selection Principles

- Prioritize nitrile coating for oily environments, latex coating for dry/rough surfaces, and PU coating for fine operations.

- Choose nitrile material when handling chemicals (latex is easily corroded), and avoid latex coating if you have allergies (contains natural proteins).

- For high-risk scenarios (e.g., cutting, impact), select gloves with cut-resistant liners (HPPE/aramid) or TPR impact-resistant structures.

When Should You Wear Rubber Coated Gloves?

The answer lies in matching the scenario to protection needs:

- Wear HORBEST rubber coated gloves when handling oil, chemicals, or sharp objects.

- Wear HORBEST rubber coated gloves for precision operations requiring anti-static protection or sensitive touch.

- Wear HORBEST rubber coated gloves during heavy-duty tasks involving impact, abrasion, or puncture risks.

HORBEST is committed to delivering high-quality rubber coated gloves tailored to diverse professional needs. With strict quality control and compliance with international standards (CE/ANSI), HORBEST ensures your hands are protected wherever safety matters most.

Shop Now

Ready to improve your safety and productivity? Explore our range of:

Rubber Coated Cotton Gloves

Rubber Palm Coated Gloves

Rubber Coated Kevlar Gloves

Coated Rubber Grip Gloves

Available in various sizes and styles—including 6-pack bundles, bulk pricing, and OSHA 10 compliant models.

👉 Buy now and experience the best in hand protection!

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599