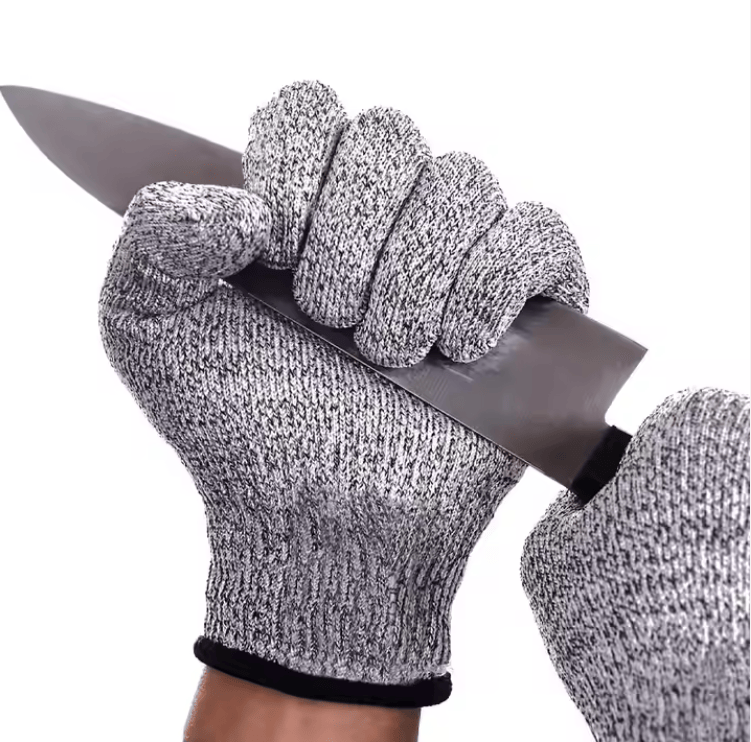

Level 5 Cut Resistant Gloves

•Material: HHPE

•Type : Knitted Working Safety Gloves

•Weight:31-63g

•Features: Comfortable ,Breathable , Durable , Protective

• Cut -Reistance: 5 Level Anti-Cut

•Color : Grey

•Application, For Kitchen Construction ,Industry , Gardening , Repairing and daily safety working

•Packing :1 pair per Opp Bag

HORBEST Level 5 Cut Resistant Gloves: Ultimate Protection & Smart Selection Guide

When it comes to hand safety in high-risk cutting scenarios, HORBEST level 5 cut resistant gloves stand out as the gold standard. As the highest cut protection grade under the EN 388 international standard, these gloves deliver unmatched defense against sharp hazards, making them a must-have for professionals and safety-focused users worldwide.

What Cut Protection Level Is Level 5 Cut Resistant Gloves?

HORBEST level 5 cut resistant gloves represent the top-tier protection for manual cutting tasks, with a cut index ≥20.0 as defined by the EN 388 standard. This means they can effectively withstand cuts from industrial knives, glass shards, metal edges, and other sharp objects—even handling high-intensity scenarios like slaughtering, heavy metal processing, and glass handling.

Key Details

- Standard Compliance: Adheres to the EU BS EN 388:2003 standard (equivalent to Australia/New Zealand AS/NZS 2161.3), which grades cut resistance from Level 1 to Level 5 (Level 5 being the highest).

- Testing Method: Samples are taken from the palm and cut back and forth with a rotating blade. The number of rotations to cut through the sample is recorded and compared to a standard cotton fabric, with a higher index indicating stronger protection.

- Material Strength: Typically crafted from Dyneema/Spectra fibers (directly achieving Level 5), Kevlar fibers (Level 4-5), or stainless steel wire mesh (maximum cut resistance). These materials are 5-10 times stronger than steel by weight.

- Application Scenarios: Essential for high-risk tasks including livestock slaughtering, meat cutting, glass handling, metal product processing, and mechanical maintenance—serving as the final line of hand protection.

How to Choose the Right HORBEST Level 5 Cut Resistant Gloves?

Selecting the perfect HORBEST level 5 cut resistant gloves hinges on three core factors: scenario adaptation, material matching, and wearing comfort, combined with compliance verification to avoid mistakes.

1. Lock in Your Usage Scenario (Core Premise)

Different scenarios demand specific additional functions—clarify your needs first:

- Food Processing/Kitchen (Meat Cutting, Fish Cleaning, Vegetable Chopping): Prioritize food-grade materials (FDA-certified), easy-to-clean, and odor-free options like Dyneema or stainless steel wire mesh gloves. Avoid latex coatings (prone to oil adhesion).

- Industrial Settings (Metal Processing, Glass Handling): Focus on wear resistance and puncture protection. Choose Kevlar or HPPE blended gloves with nitrile/latex coatings to enhance grip in wet or oily environments.

- Emergency Rescue/Outdoor Work: Opt for lightweight, breathable, and tear-resistant Dyneema gloves that balance protection and flexibility. Avoid bulky full stainless steel gloves that hinder operation.

- High-Temperature Work (Welding Assistance, Thermal Processing): Prefer Kevlar materials (heat-resistant up to 400°C) and avoid regular HPPE gloves (prone to deformation above 70°C).

2. Match Core Materials (Determine Protection & Experience)

Each core material of HORBEST level 5 cut resistant gloves has its own advantages—choose based on your needs:

- Stainless Steel Wire Mesh: Offers the strongest cut and puncture resistance, ideal for extreme cutting scenarios (e.g., slaughtering, heavy metal processing). Complies with BS EN 1082-1 (weight ≤4kg/m²) but may cause fatigue during long-term wear. Advantage: High-temperature sterilizable.

- Dyneema/Spectra Fibers: 10 times stronger than steel, lightweight, waterproof, UV-resistant, and soft/flexible. Suitable for most scenarios (kitchen, industrial, daily use). Disadvantage: Not heat-resistant—avoid heat sources.

- Kevlar Fibers: 5 times stronger than steel, flame-retardant, and acid/alkali resistant. Ideal for high-temperature or chemical contact scenarios. Some coated models enhance grip. Disadvantage: Water slightly reduces strength—dry promptly after use.

- Blended Materials (HPPE + Steel Wire/Kevlar): Balance protection and comfort. For example, HPPE + steel wire gloves offer Level 5 cut resistance while being lighter than pure steel wire models—an excellent all-purpose choice.

3. Focus on Wearing & Practical Functions (Avoid Discomfort)

- Size Fit: Choose a snug size (XS-XL). Oversized gloves compromise operation and protection; undersized ones restrict blood circulation. Prefer ambidextrous or left/right-specific designs.

- Comfort: Prioritize breathable fabrics (e.g., knitted liners) for all-day wear without sweating. For precise tasks (e.g., assembly, chopping), select thin, finger-flexible models to avoid reduced touch sensitivity from thick coatings.

- Additional Functions: Select coatings based on needs (nitrile for slip resistance, latex for strong grip) and adjustable wrist straps (to prevent slipping). For food scenarios, avoid odorous or lint-shedding materials.

4. Verify Compliance & Quality (Avoid “Fake Level 5”)

- Mandatory Certifications: Must meet EN 388 (cut index ≥20.0). For food scenarios, additional FDA 21 CFR 177.2800 certification is required. For industrial use, reference ANSI/ISEA 105 A9 (highest cut grade).

- Quality Checks: Ensure no damage, loose threads, or missed stitches on the surface; coatings should be uniform and non-peeling. Clear labeling (material, grade, applicable temperature) is a must—avoid uncertified “three-no products” with substandard protection.

5. Avoid Common Misconceptions

- Don’t Blindly Choose “Thicker = Better”: Thicker gloves don’t guarantee stronger protection but hinder flexibility. For example, thin Dyneema gloves are more practical for kitchen chopping than thick stainless steel ones.

- Don’t Neglect Cleaning Needs: For frequent-use scenarios (e.g., kitchen), select machine-washable models to avoid the hassle of special care.

HORBEST Level 5 Cut Resistant Gloves: Scenario-Material-Function Matching Table

| Application Scenarios | Recommended Materials | Core Function Highlights | Mandatory Compliance Standards | Notes |

|---|---|---|---|---|

| Food Processing/Kitchen (Meat Cutting, Fish Cleaning, Vegetable Chopping) | Dyneema/Spectra Fibers / Stainless Steel Wire Mesh | Food-grade safety (odorless, non-contaminating), easy to clean, puncture-resistant | BS EN 388 (cut index ≥20.0), FDA 21 CFR 177.2800, BS EN 1082-1 (weight ≤4kg/m²) | Stainless steel wire mesh models may cause fatigue; opt for lightweight titanium-blended versions. Avoid latex coatings (oil-adhesive). |

| Industrial Metal Processing (Cutting, Assembly, Mechanical Maintenance) | Kevlar Fibers (Nitrile Coated) / HPPE + Steel Wire Blend | Wear-resistant, oil-resistant, strong grip, tear-resistant | BS EN 388, BS EN 420 (skin compatibility) | Kevlar strength slightly decreases when wet; dry promptly after use. Keep away from strong acids and alkalis. |

| Glass Handling/Sheet Metal Processing | Dyneema/Spectra Fibers (Uncoated) | Lightweight, flexible, UV-resistant, waterproof, blade-slip resistant | BS EN 388, Puncture Resistance ≥Level 4 | Avoid heat sources above 70°C; do not wash in hot water for more than 10 minutes. |

| Emergency Rescue/Outdoor Work | Blended Materials (Kevlar + Dyneema) | Tear-resistant, breathable, balanced protection and flexibility | BS EN 388, ANSI/ISEA 105 A9 Grade | Avoid serrated or wavy blades (protection may fail). |

| High-Temperature Work (Welding Assistance, Thermal Processing) | Kevlar Fibers (Pure Woven) | Flame-retardant, heat-resistant up to 400°C, high chemical stability | BS EN 388, Flame Retardant Standard Compliance | Do not contact high-temperature metals directly; can be worn over heat-resistant gloves. |

HORBEST Exclusive Selection Tips

- Prioritize “scenario → material” matching, then choose thickness based on task precision: thin Dyneema for precise tasks (e.g., chopping, assembly) and stainless steel wire mesh or blended materials for heavy-load scenarios (e.g., slaughtering, metal cutting).

- All HORBEST level 5 cut resistant gloves feature clear compliance labels—look for “BS EN 388 Level 5” and “cut index ≥20.0” when purchasing to avoid counterfeits.

- For food scenarios, select HORBEST Dyneema food-grade models (FDA-certified); for industrial use, choose Kevlar nitrile-coated models (dual advantages of wear resistance and slip resistance); for cost-effectiveness, opt for HPPE + steel wire blended models (balanced protection and comfort).

Choose HORBEST Level 5 Cut Resistant Gloves for Uncompromised Safety

HORBEST level 5 cut resistant gloves are engineered with premium materials, strict compliance, and user-centric design—delivering not just top-tier protection but also long-lasting durability and comfort. Whether you’re a professional in food processing, metalworking, or emergency rescue, or a home cook prioritizing safety, HORBEST has the perfect level 5 cut resistant gloves to meet your needs.

Don’t compromise on hand safety—invest in HORBEST level 5 cut resistant gloves today and work with confidence, no matter the challenge.

Level 5 Cut Resistant Gloves:

✔ Size & Thickness Design: Flexible Fit for Various Hand Types

•Available Sizes: M (21 cm), L (21 cm), XL (23 cm)

•Designed to fit different hand shapes for improved stability and comfort during operation.

•Glove Thickness: Approx. 1.9 mm

•Provides sufficient cut protection while maintaining excellent finger sensitivity and freedom of movement.

✔ Material Structure: High-Density Protection + Durable Anti-Slip Surface

•Material: Blend of High-Density Polyethylene (HDPE) and nylon fibers

•Offers outstanding cut resistance and flexibility, suitable for extended wear.

•Surface Coating: PU (Polyurethane)

•Enhances grip and safety with an anti-slip finish, ideal for handling metal, tools, and slippery objects.

✔ Versatile Application: Suitable for Cleanrooms and Heavy-Duty Work

Level 5 cut resistant gloves, cut-resistant gloves are suitable for a wide range of work environments, including:

•Cleanroom operations

•Automotive repair and machinery maintenance

•Plastic processing and molding

•Metalworking, cutting, and handling

•Construction sites and rough material handling

✔ Certified Protection Performance: Tested to EN 388 Standard

This glove meets EN 388 test standards and offers the following exceptional protective features:

•Tear Resistance Level 5:

Withstands high-risk tear scenarios, such as steel handling and stacking on construction sites.

•Abrasion Resistance Level 5:

Withstands up to 8000 abrasion cycles, ideal for rough-surface tasks like carpentry and masonry.

•Puncture Resistance Level 3:

Effectively resists punctures from nails, rebar, and sharp debris—perfect for waste sorting and steelwork.

•Cut Resistance Level 5 (per ISO 13997 test):

Withstands 10–15 Newtons of force, suitable for medium-risk tasks such as auto repair, kitchen cutting, and plastic molding.

✔ High-Performance & Budget-Friendly: Smart Investment in Hand Protection

Level 5 cut resistant gloves offer rare dual advantages of high protection and comfort at an affordable price.

Whether you’re on a clean production line, in a repair shop, or at a construction site, these gloves are your ideal safety companion.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599