Levels, Uses & Buyer Guide

Best Cut Resistant Work Gloves for Industrial Safety

Introduction

There is no single “best” cut resistant work glove for every job.

The right choice depends on cut level, application, grip conditions, and dexterity requirements.

This guide helps safety managers, buyers, and workers choose the best cut resistant work gloves by matching real work scenarios with appropriate protection levels—rather than relying on marketing claims.

How We Define “Best” Cut Resistant Gloves

The best cut resistant gloves are those that:

-

Match the actual cutting hazard

-

Balance protection and dexterity

-

Provide reliable grip for the environment

-

Comply with recognized standards such as ANSI/ISEA and EN 388

Best Cut Resistant Work Gloves by Cut Level

🔹 Light Cut Resistance (ANSI A2–A3)

Best for: warehouse picking, packaging, light assembly

Why choose these:

-

Excellent finger dexterity

-

Lightweight and breathable

-

Reduced hand fatigue during long shifts

Typical materials: HPPE blends with PU coating

👉 Ideal when workers handle cartons, plastic straps, or light sharp edges.

🔹 Medium Cut Resistance (ANSI A4–A5)

Best for: metal handling, automotive assembly, glass handling

Why choose these:

-

Balanced cut protection and flexibility

-

Strong abrasion resistance

-

Most commonly used level in industrial settings

Typical materials: HPPE + glass/steel fiber blends, nitrile coating

👉 This range represents the most popular “best cut resistant gloves” category.

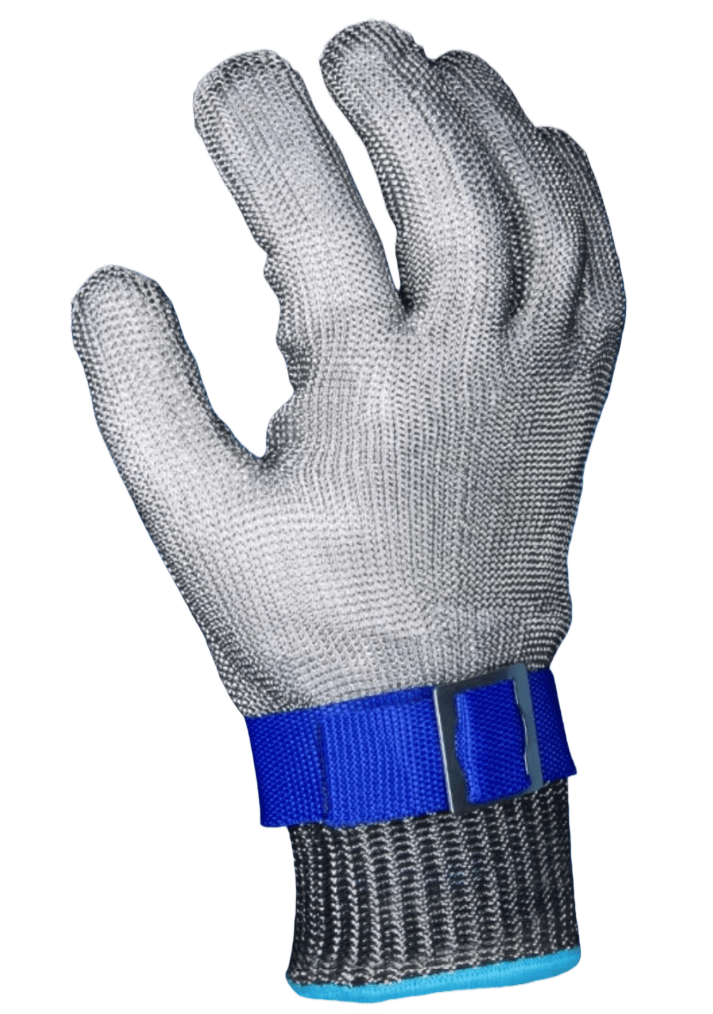

🔹 Heavy Cut Resistance (ANSI A6–A9)

Best for: sharp metal sheets, heavy fabrication, high-risk tasks

Why choose these:

-

Maximum cut protection

-

Designed for severe cutting hazards

Trade-off: reduced dexterity and thicker feel

⚠️ These gloves are not recommended for precision tasks.

Best Cut Resistant Gloves by Application

| Application | Typical Risk | Recommended Cut Level |

|---|---|---|

| Warehouse & logistics | box cutters, sharp edges | A2–A4 |

| Metal fabrication | sharp sheet metal | A4–A6 |

| Glass handling | sharp glass edges | A5–A6 |

| Automotive assembly | sharp parts, oils | A4–A5 |

| Construction & maintenance | mixed sharp hazards | A3–A5 |

👉 For rating systems and testing methods, see cut resistant gloves standards.

Grip & Coating: Often More Important Than Cut Level

Many glove failures occur not from cuts—but from dropped parts.

-

PU coating: best dexterity, dry handling

-

Nitrile coating: strong grip for oily/wet environments

-

Latex coating: flexible grip (not suitable for latex-sensitive users)

Choosing the wrong coating can make even a high cut-level glove unsafe.

Common Buyer Mistakes (Why “Best” Often Fails)

-

Buying the highest cut level “just in case”

-

Ignoring grip conditions

-

Overlooking comfort and fatigue

-

Not checking standard compliance

The best cut resistant work gloves are those workers actually wear correctly.

Final Recommendation

Choose cut resistant gloves based on risk assessment, not labels.

Matching cut level, coating, and environment leads to safer and more productive workplaces.

👉 Learn fundamentals at cut resistant gloves.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599