Levels, Materials, Standards & Buying Guide

Cut Resistant Gloves (Anti-Cut Gloves) for Work Safety

Hand cuts are one of the most common workplace injuries—especially when handling metal edges, glass, blades, packaging knives, and sharp parts. If your hands face cut or slash risks in daily tasks, cut resistant gloves are a safer choice for both industrial work and home use.

This guide explains cut resistant glove levels, the ANSI/EN 388 standards, common materials, coatings, and how to choose the right cut resistant gloves for work without sacrificing comfort or dexterity.

What Are Cut Resistant Gloves?

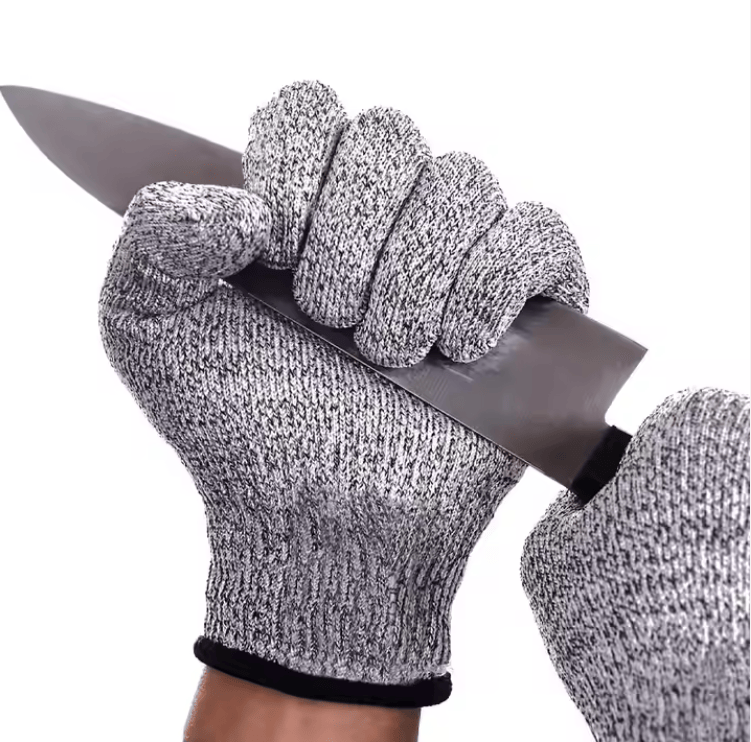

Cut resistant gloves (also called anti cut gloves or safety anti cutting gloves) are protective gloves made with high-strength fibers engineered to reduce the risk of cuts, punctures, abrasion, and tearing during manual handling.

Important: cut resistant gloves are cut-resistant, not cut-proof. They reduce risk from hand-held blades and sharp edges, but they are not designed for saw teeth or high-speed cutting tools.

Cut Resistant Gloves Levels & Standards (ANSI vs EN 388)

Most professional buyers compare gloves using two systems:

1) ANSI/ISEA 105 Cut Levels (A1–A9)

ANSI uses a 9-level scale where higher levels mean higher cut resistance; an A1 glove may withstand about 200 grams, while A9 can exceed 6,000 grams in standardized testing.

Quick guidance (task-based):

-

A2–A3: light handling, general warehouse picking

-

A4–A5: metal handling, automotive assembly, glass handling (balanced)

-

A6–A9: heavy fabrication, very sharp edges (max protection, lower dexterity)

2) EN 388 (Europe) + ISO 13997 (A–F)

EN 388 evaluates mechanical risks such as abrasion, tear, puncture, plus cut testing. The 2016 update formally includes ISO 13997 (TDM cut test) and reports cut performance using A–F letters (F highest).

Rule: ANSI A-levels and EN 388 letters are not 1:1 interchangeable. Use the rating system required by your workplace or region.

Cut Resistant Glove Materials (What They’re Made Of)

Different fibers change cut level, comfort, heat resistance, and price.

| Material | Key Benefits | Best For |

|---|---|---|

| HPPE / UHMWPE (e.g., Dyneema/Spectra type) | lightweight, high cut resistance, breathable | logistics, general work, glass handling |

| Aramid (Kevlar®) | cut + heat resistance (good for hot tasks) | metalwork, welding support tasks, maintenance |

| Glass / Steel fiber blends | higher cut levels, strong reinforcement | sharp metal edges, heavy duty work |

| Stainless steel mesh / chainmail | maximum cut resistance, washable | food processing, butchering, high-risk cutting |

Coatings: Grip Matters as Much as Cut Level

Cut resistance alone is not enough. The right coating improves grip and reduces drops (which cause injuries).

-

PU coating: best dexterity, good for dry handling and precision work

-

Nitrile coating: stronger abrasion resistance, better for oily or wet surfaces

-

Latex coating: flexible, strong grip (not ideal for latex-sensitive users)

Choose the Right Cut Resistant Gloves for Work (Fast Selection)

Step 1 — Identify your main hazard

-

Sharp edges (metal/glass): prioritize higher cut resistance (A4–A6 typical)

-

Packaging knives: moderate cut + high dexterity (A2–A4)

-

Oily parts/machinery: nitrile coating for grip

-

Food processing: washable materials, consider steel mesh for highest cut tasks

Step 2 — Balance protection vs dexterity

Higher cut levels can mean thicker yarn and reduced finger control. Choosing “the highest level” isn’t always safer—reduced dexterity can increase accidents.

Step 3 — Match the environment

-

Hot work: aramid/Kevlar type blends

-

Wet/oily: nitrile coating

-

Long wear: breathable liner, proper sizing

Recommended Cut Levels by Job (Practical Matrix)

| Job Scenario | Typical Risks | Recommended Cut Level | Recommended Coating |

|---|---|---|---|

| Warehouse picking & packaging | carton knives, sharp corners | A2–A4 | PU / thin nitrile |

| Metal fabrication & sheet handling | sharp metal edges | A4–A6 | nitrile |

| Glass handling & installation | sharp glass edges | A5–A6 | nitrile / textured |

| Automotive assembly | sharp parts, oils | A4–A5 | nitrile |

| Construction & demolition | mixed sharp hazards | A3–A5 | nitrile / latex |

| Food processing (butchering) | blades, slicing | High (task-based) | steel mesh / food-safe options |

Common Mistakes Buyers Make

-

Buying the highest cut level “just in case”

Too thick = less control, more fatigue, sometimes more accidents. -

Ignoring grip conditions

If you handle oily parts, “high cut” without nitrile grip is often a downgrade. -

Not checking standards labeling

Always verify ANSI/EN ratings on the glove tag or spec sheet. -

Wrong sizing

Loose gloves reduce control; overly tight gloves reduce circulation and comfort.

Cleaning, Storage & Replacement

-

Wash according to material: most textile cut gloves can be washed and air-dried.

-

Avoid direct sunlight drying for long periods.

-

Replace gloves if there are holes, severe thinning, or coating failure.

-

Steel mesh/chainmail gloves should be cleaned thoroughly for hygiene (food-use).

Why Choose BEST Cut Resistant Gloves

ESDBEST provides multiple cut resistant glove options across different materials and cut levels—suitable for glass handling, metal fabrication, logistics, and industrial workplaces.

FAQ (for Featured Snippets)

Q1: Are cut resistant gloves cut proof?

No. They reduce risk from hand-held sharp edges/blades but are not designed for saws or high-speed cutting tools.

Q2: What cut level gloves do I need for warehouse work?

Most warehouse picking tasks use ANSI A2–A4, balancing dexterity and protection.

Q3: Is higher cut level always safer?

Not always. Higher levels can reduce dexterity and increase fatigue, which may raise accident risk.

Q4: What’s the difference between ANSI and EN 388 cut ratings?

ANSI reports cut performance on A1–A9 scale; EN 388 uses mechanical risk scores and (for ISO cut) A–F letters. They are not 1:1 interchangeable.

Q5: What coating is best for oily environments?

Nitrile coatings typically perform better for oil resistance and grip.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599