Anti Static Wipes

Anti Static Wipes: Essential Tool for Sensitive Electronic Cleaning

In the realm of electronics manufacturing, laboratory research, and cleanroom operations, maintaining static-free and dust-free environments is critical to protecting sensitive components. Anti static wipes have emerged as an indispensable solution, designed to tackle both contamination and electrostatic risks. This article delves into what anti static wipes are, their key applications, advantages, usage methods, and details of our high-quality product line.

What Is an Anti Static Wipe?

An anti static wipe is a specialized cleaning cloth engineered to clean surfaces without generating static electricity. As a type of anti static cleaning wipes, it is available in both disposable and reusable options, often infused with anti-static agents or supplied pre-moistened. Crafted for sensitive electronic environments, these anti-static wipes combine cleaning efficiency with electrostatic control, making them safe for delicate equipment that is prone to damage from electrostatic discharge (ESD).

Key Applications of Anti Static Wipes

Anti static wipes find extensive use across various industries due to their dual functionality of cleaning and static prevention. Here are their primary applications:

- Electronics (Monitors, Keyboards, Phones): Anti static wipes for electronics, such as anti static computer wipes and anti static monitor wipes, remove dust and prevents static build-up that can harm internal components, ensuring the smooth operation of devices.

- Camera Lenses & Optical Devices: Anti static anti fog lens wipes clean delicate surfaces without scratching or leaving static residue, maintaining optical clarity.

- Printers & Copiers: Reduces paper jamming caused by static charges, improving the efficiency of office equipment.

- Cleanroom Equipment: Anti static cleanroom wipes adhere to strict dust and static control standards, crucial for industries like semiconductor manufacturing and pharmaceutical production.

- CDs/DVDs/Blu-rays: Avoids static charges that attract dust and damage discs, preserving data storage quality.

- Printed Circuit Boards (PCBs): Cleans safely without ESD risk, a vital step in PCB assembly and maintenance to prevent component failure.

Why Choose Anti Static Wipes?

Opting for anti static wipes offers numerous benefits for both equipment and operations:

- Prevents Electrostatic Discharge (ESD): Critical when cleaning microchips, circuit boards, and other ESD-sensitive components, as ESD can cause irreversible damage.

- Attracts Less Dust: As effective anti static dust wipes, they minimize dust attraction caused by static charges, keeping surfaces cleaner for longer.

- Non-abrasive: Gentle on delicate surfaces such as screens, lenses, and PCBs, avoiding scratches or surface damage.

- Improves Equipment Life & Performance: By reducing contamination and static-related issues, anti static wipes extend the lifespan of equipment and enhance its operational efficiency.

How to Use Anti Static Wipes

Using anti static wipes correctly ensures optimal results and safety:

- Take one wipe from the sealed package (if pre-moistened) to maintain its anti-static properties and cleanliness.

- Wipe down the target surface gently in a single direction to avoid spreading dust or causing scratches.

- Allow the surface to air-dry if the wipe is pre-moistened – no rinsing is required.

- Dispose of the wipe properly after use unless it is designed for reuse.

Our Premium Anti Static Wipe Products

We offer a range of high-performance anti static wipes tailored to meet the demands of cleanroom and ESD-sensitive environments. Similar to trusted options like 3m anti static wipes, our products deliver reliable ESD protection and cleaning efficacy. Here are our key products:

Product Specifications (General)

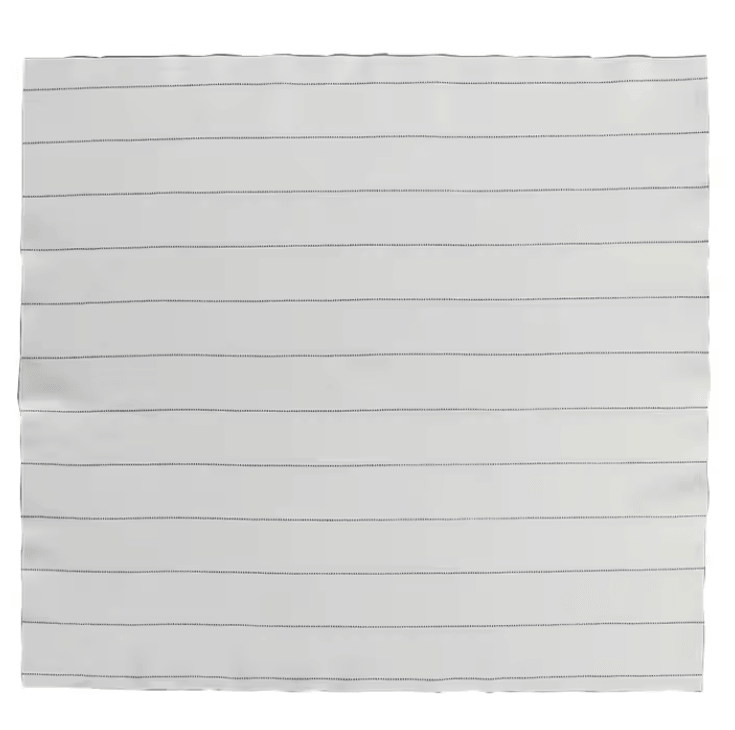

- Material: 78% polyester + 20% nylon with 2% conductive carbon yarns

- Cutting Edge: Laser sealed

- Surface Resistance: 10^6 – 10^9 Ω

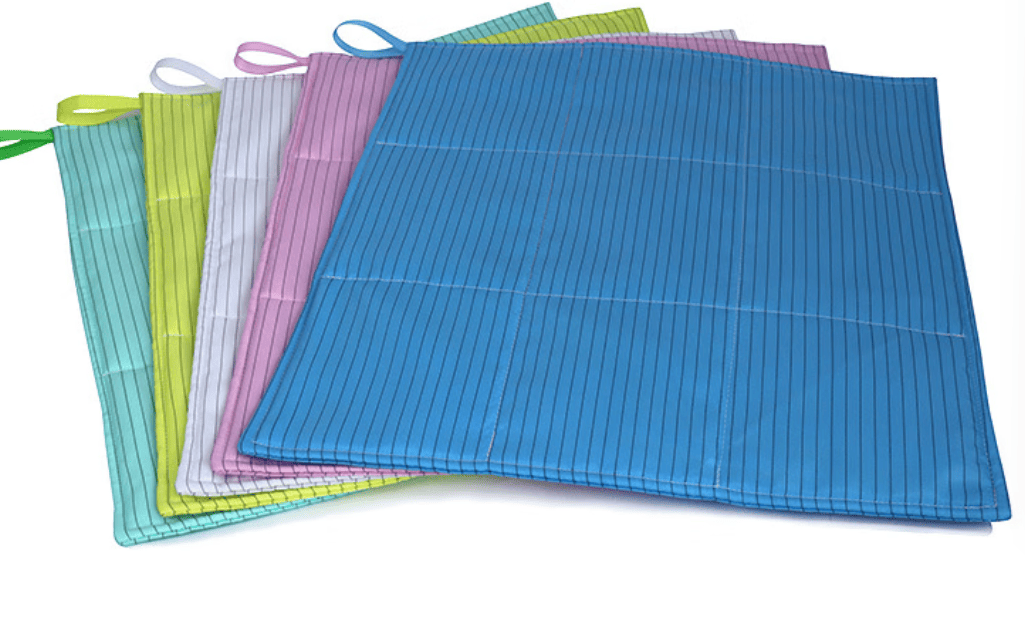

- Color: White

- Size: 9” x 9”

- Cleanroom Grade: Class 100 / 1000

- Weight per Square Meter: 160g/sqm

- Packing: 100pcs/bag

- MOQ: 1 bag

Product Models

- EF2005-9: 9inch*9inch Clean Room ESD Safe Sub Microfiber Wiper, 120g/sqm

- EF2005-N9: 9inch*9inch Clean Room ESD Safe Polyester Wiper, 120g/sqm

- EF2005-S9: 9inch*9inch Clean Room ESD Safe Microfiber Wiper, 160g/sqm

Key Advantages of Our Anti Static Wipes: Ideal for wiping exterior areas of products in ESD-sensitive areas and cleaning process tools. Made of 100% continuous polyester filaments with conductive carbon yarns, featuring good solvent resistance, lint and particle free properties. Static dissipative on both sides (unlike single-sided alternatives). Available sizes also include 4”*4” and 6”*6”. Cleanroom Class Compatibility: Class 100 – Class 1000 with low particulate release.

📞 Contact Us Today

For bulk orders, competitive quotes, or professional product guidance, our expert team is ready to assist you:

- Email: sales2@esdbest.com

- Phone: +86 137 1427 2599