Wrist Straps

How to use wrist straps correctly ?

Using an ESD (Electrostatic Discharge) wrist straps correctly is crucial for protecting sensitive electronic components from static damage. Here’s a step-by-step guide to ensure you’re using it the right way:

Purpose of an wrist straps

An ESD strap safely channels static electricity from your body to ground, preventing it from discharging into electronics.

How to Use an ESD Wrist Strap Properly

1. Wear the Strap on Your Skin

Wrap the strap around your wrist, ensuring it’s in direct contact with your skin (no sleeves in between).

It should be snug but not too tight—think comfortable watch fit.

2. Connect the Ground Cord

The strap typically has a coiled ground wire with a banana plug or alligator clip at the end.

Plug this into:

A grounded ESD mat

A common ground point (often found at workstations)

Or a grounded outlet adapter (for personal workbenches)

3. Ensure the Ground Connection is Proper

The ground wire must lead to a true earth ground.

Many modern ESD mats and benches have built-in grounding ports.

DO NOT clip the strap to painted or insulated metal—it won’t work.

4. Test the wrist straps

Use an ESD wrist strap tester (available for $10–$50) to ensure it’s working.

Many workplaces require you to test it daily before starting work.

5. Stay Grounded

You must wear the strap the entire time you’re handling sensitive components.

If you get up and walk away, reattach when you return.

Common Mistakes to Avoid

| ❌ Mistake | ✅ Correct Practice |

|---|---|

| Wearing over clothing | Strap must touch skin |

| Not connecting to ground | Always connect to a grounded point |

| Only touching metal case | Metal may not be grounded |

| Removing strap mid-task | Stay strapped until finished |

Tip for DIY or Home Users

If you’re working at home and don’t have a grounding point:

Use a 3-prong outlet with a grounding plug adapter.

Or ground the strap to an unpainted metal part of a plugged-in power supply (only if you know it’s grounded—this carries some risk if not properly done).

What Is an ESD Wrist Straps?

An ESD wrist strap, also known as an anti-static wristband, is a personal grounding device worn to safely discharge static electricity from a person to the ground. It is one of the most essential tools in any ESD control program, especially in electronics manufacturing, repair, or cleanroom environments.

Why Is It Necessary?

Humans constantly generate static electricity from friction (e.g., walking on carpet, clothing, etc.). This static can discharge into sensitive components like microchips, circuit boards, or semiconductors, causing:

Immediate damage (catastrophic failure)

Latent damage (component may fail later)

Even a static charge as low as 100 volts can damage modern electronics. (Humans only feel shocks at ~2,000V!)

How Does It Work?

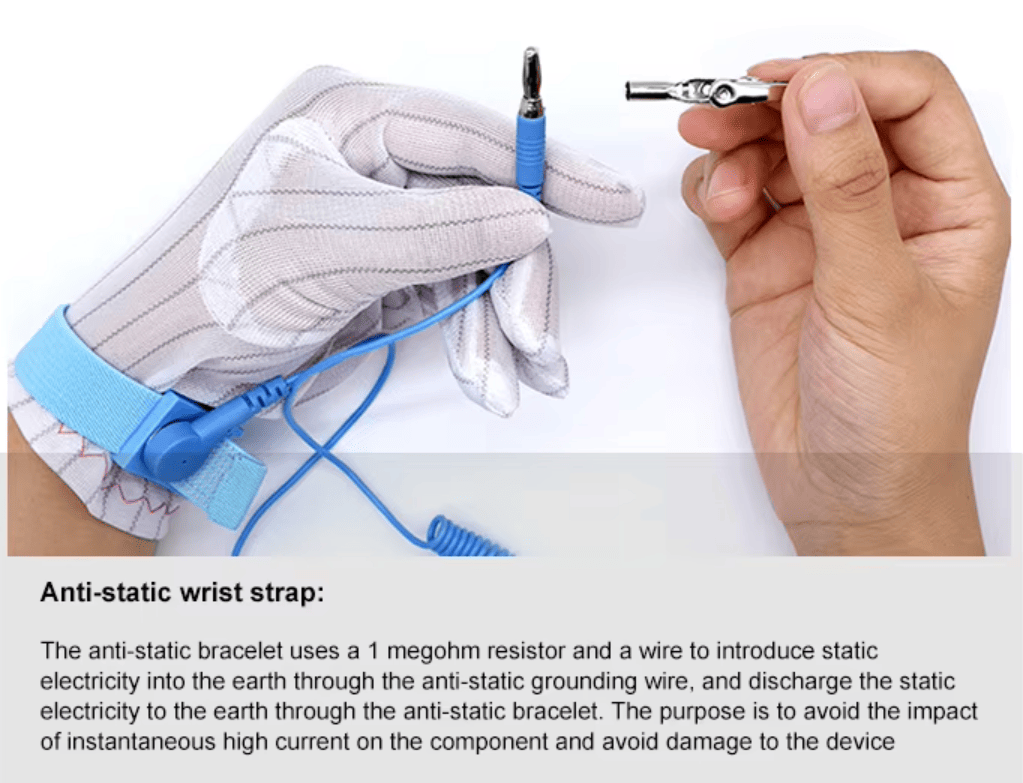

An ESD wrist strap has three core components:

Wristband (Conductive)

Usually made from a comfortable fabric laced with conductive threads.

Maintains electrical contact with your skin.

Grounding Cord

Alligator clip

Banana plug

Grounding jack or plug

A coiled cord that connects the wristband to a ground point.

One end attaches to the wristband via a snap or banana plug, and the other end connects to ground using:

Grounding Point

A grounded ESD mat, workstation, power outlet ground pin, or common ground system.

💡 The wrist strap ensures your body stays at the same potential as grounded surfaces, preventing any electrostatic discharge.

Types of ESD Wrist Straps

➤ By Band Type:

| Type | Description | Use Case |

|---|---|---|

| Fabric Band | Soft, adjustable, woven with conductive fibers | Most common and comfortable |

| Metal Band | Stainless steel, adjustable links | More durable, used in cleanrooms |

| Disposable | Single-use adhesive bands | Ideal for visitors or one-time use |

➤ By Ground Cord:

| Type | Description |

|---|---|

| Straight Cord | Basic, shorter range |

| Coiled Cord | Extends flexibility without clutter |

| Dual Wire Cord | Redundant ground path; used in critical ESD areas for monitoring |

How to Test an ESD Strap?

Frequent testing ensures your strap is working. Use an ESD wrist strap tester, which checks the resistance range.

Acceptable range: 1 × 10⁵ Ω (100KΩ) to 1 × 10⁷ or 10⁹ Ω (10MΩ – 1GΩ)

Most testers have green = pass, red = fail

Some workplaces require daily testing with a logbook entry.

Maintenance & Care

Clean the band (especially fabric ones) regularly with mild soap and water.

Never machine wash unless specified.

Inspect for wear, breakage, or poor contact.

Replace grounding cords or wristbands as needed.

Common Mistakes to Avoid

| Mistake | Why It’s a Problem |

|---|---|

| Wearing over clothes | No skin contact = no grounding |

| Not grounded properly | The strap becomes ineffective |

| Using a broken cord | No discharge path |

| Touching sensitive components before grounding | Static might already discharge |

| Assuming it works without testing | Risk of silent failures |

Advanced Notes (for Engineers / Labs)

Dual-wire straps: Provide a backup ground and allow continuous monitoring.

Continuous monitors: Some ESD systems include monitors that alert if the strap fails or is disconnected.

Compliance: Should meet ANSI/ESD S1.1 and be part of a broader ESD Control Program (per ANSI/ESD S20.20).

Recommended Brands (Reliable)

3M

HORBEST

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599