How esd mats work ?

In mobile phone assembly workshops or chip laboratories, workers always operate on special workbenches—that’s the esd mat. You may wonder why a seemingly ordinary mat can become the “protector” of electronic components? The answer lies in its unique working logic to combat static electricity.

Static Electricity: The “Invisible Killer” of Electronic Components

To understand esd mats, we first need to recognize the hazards of static electricity. When we dress or walk daily, friction between different materials generates static electricity, and the voltage can even reach tens of thousands of volts in dry environments. This static electricity is harmless to the human body, but it is a “fatal threat” to precision electronic components such as chips and capacitors: high voltage may break down the insulation layer of components, leading to direct scrapping; even if it is not damaged on the spot, it will leave “hidden injuries”, causing frequent crashes and shortened service life of the equipment during later operation. What’s more troublesome is that ordinary rubber mats and plastic mats will囤积 static electricity like “charge warehouses”, which instead increases the risk.

Core Principle: “Dredge” Rather Than “Block”

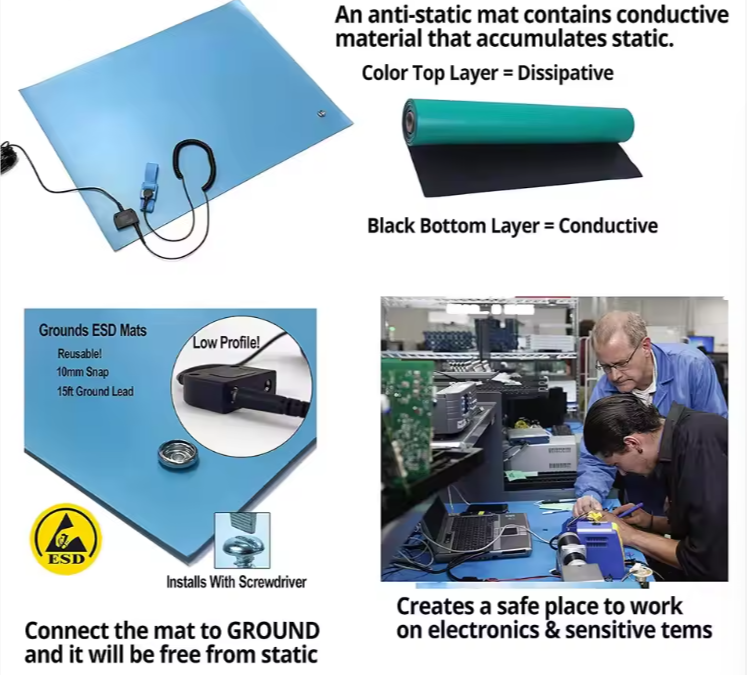

The wisdom of esd mats lies in the fact that they do not “confront” static electricity head-on, but solve the problem by “dredging”. The key lies in the special material formula—uniformly mixing “conductive fillers” such as carbon black and metal oxides into the rubber or PVC base material. These fillers are like countless tiny “charge channels”, weaving a three-dimensional network inside the mat.

This design endows the mat with “static dissipative property”: it neither traps charges like insulating materials nor makes current flow instantly like metals (to avoid impacting components). According to international standards, its surface resistance must be controlled between 10⁶-10¹¹Ω to ensure that static electricity can move slowly within a few seconds. When electronic components are placed on the esd mat, the static electricity on the surface will spread to the entire mat along the “channels”, avoiding local charge concentration. HORBEST esd mats are precisely manufactured with this advanced material formula, ensuring excellent static dissipative performance.

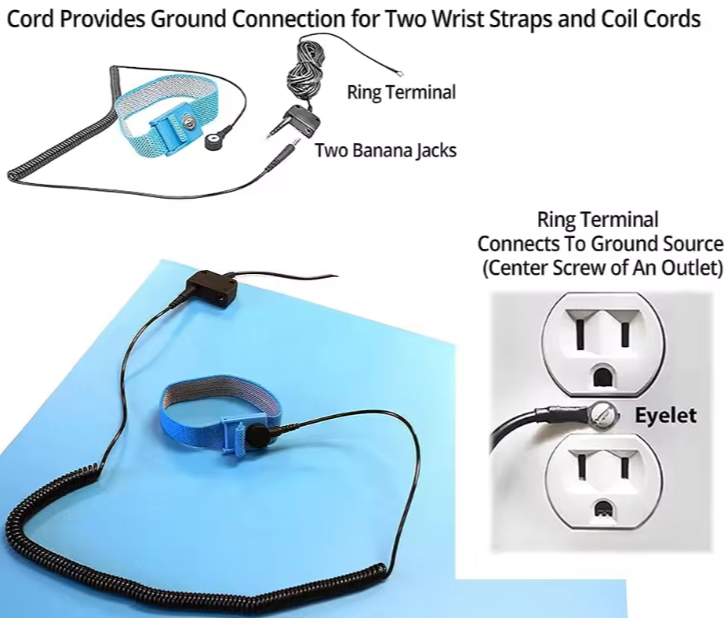

Key Partner: ESD Mat Grounding Is Indispensable

Dredging alone is not enough; static electricity ultimately needs to “go home”—the earth is the best destination. Esd mats must be used with a grounding system: metal grounding terminals are reserved on the edge of the mat, which are connected to the grounding electrode of the workshop through special wires. In this way, the charges on the mat will flow into the earth along the wires, just like opening a flood discharge channel for floods, fundamentally eliminating accumulation.

Here’s a detail: the resistance of the grounding wire must be ≤1MΩ, and it is necessary to check regularly whether it is loose or broken. Once esd mat grounding fails, the mat will turn back into a “static warehouse” and lose its protective effect.

Daily Maintenance: Keep Protection Effective

Esd mats are not “one-time use and permanent protection”. Oil stains and dust on the surface will block the conductive channels, leading to performance degradation, so special cleaning agents should be used for wiping, and corrosive solvents such as alcohol and gasoline cannot be used; sharp tools are easy to scratch the mat and damage the internal conductive network, so extra care should be taken during operation; environmental humidity is also crucial. In dry seasons (humidity below 30%), humidifiers should be used, because humid air can help neutralize static electricity.

From electronics factories to laboratories, esd mats use the simple logic of “dredging + grounding” to protect countless precision components. It seems inconspicuous, but it is an indispensable “invisible guard” in the modern electronic industry—it is the scientific and technological wisdom in these details that allows our mobile phones, computers and other equipment to operate stably. If you are looking for high-quality esd mats that meet international standards and have reliable performance, HORBEST is your ideal choice. HORBEST esd mats not only have excellent static control capabilities but also have strong durability, suitable for various precision electronic operation scenarios. Choose HORBEST to provide solid protection for your electronic components and avoid losses caused by static electricity.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599