Coated Gloves

Coated Work Gloves Guide: PU, Nitrile & Rubber Coated Gloves for Industrial Safety | HORBEST

What Are Coated Work Gloves?

Popular Coated Gloves Types: Materials, Advantages & Use Cases

1. PU Coated Gloves (Polyurethane Coated Gloves)

Key Keywords: pu gloves, pu coated gloves, polyurethane pu coated gloves, polyurethane coated gloves, palm coated gloves

PU coated gloves are a top choice for tasks requiring dexterity and light protection. The polyurethane coating is thin, flexible, and offers excellent tactile sensitivity—perfect for handling small parts, tools, or electronic components.

- Advantages: Superior grip (even on dry/waxy surfaces), exceptional dexterity, lightweight, breathable, and low allergenic risk. Palm-coated designs balance protection and flexibility, while full-coated options add extra durability.

- Use Cases: Precision machining, electronic assembly, laboratory work, packaging, and light mechanical tasks.

- HORBEST PU Coated Gloves Highlight: Our polyurethane coated gloves feature a 13-gauge nylon liner with palm coating, delivering a firm grip without sacrificing agility. Ideal for workers who need to handle delicate parts or operate machinery with precision.

2. Nitrile Coated Gloves

Key Keywords: nitrile coated gloves, gloves nitrile coated, nitrile coated work gloves, firm grip nitrile coated gloves, maxiflex ultimate gloves nitrile coated product info and reviews

Nitrile coated gloves are the gold standard for heavy-duty industrial use. Nitrile—a synthetic rubber—is resistant to oils, greases, chemicals, and abrasions, making them more durable than PU or latex alternatives.

- Advantages: Exceptional oil/water resistance, superior cut/abrasion protection, firm grip (even in wet/oily conditions), and no latex allergies. Popular among professionals seeking long-lasting performance.

- Use Cases: Automotive repair, mechanical maintenance, mining, construction, oil refining, and manufacturing.

- Comparing to Maxiflex Ultimate Nitrile Coated Gloves: While maxiflex ultimate gloves nitrile coated are praised for flexibility, HORBEST’s nitrile coated work gloves raise the bar with a reinforced coating (wear resistance ≥10,000rad) and 13-gauge knitted liner. Reviews highlight our gloves’ longer lifespan and better grip in extreme oil-rich environments—perfect for 8+ hour shifts.

3. Rubber Coated Gloves (Rubber Coated Work Gloves)

Key Keywords: rubber coated gloves, rubber coated work gloves, gloves rubber coated, when should you wear rubber coated gloves

Rubber coated gloves (often made from natural rubber or synthetic rubber blends) excel at chemical and liquid protection. They’re thicker than PU or nitrile gloves, making them ideal for harsh environments.

- Advantages: Excellent resistance to water, acids, alkalis, and general chemicals; durable and puncture-resistant.

- When Should You Wear Rubber Coated Gloves?: Use them for tasks involving chemical handling, cleaning with corrosive agents, plumbing, or working with wet materials. They’re also great for outdoor jobs in rainy conditions.

- HORBEST Rubber Coated Gloves: Our rubber coated work gloves feature a heavy-duty rubber coating that repels chemicals and water, paired with a breathable cotton liner for comfort. Compliant with safety standards, they’re a reliable choice for high-risk chemical tasks.

4. Latex Coated Gloves (Latex Coated Work Gloves)

Key Keywords: latex coated gloves, latex coated work gloves

Latex coated gloves are known for their elasticity and superior grip. Made from natural rubber, they offer excellent flexibility and tactile feedback.

- Advantages: Exceptional grip (dry and slightly wet surfaces), high elasticity, and good puncture resistance.

- Disadvantages: Potential latex allergies; less resistant to oils and chemicals than nitrile.

- Use Cases: Light manufacturing, assembly line work, gardening, and tasks where dexterity and grip are critical (with no oil/chemical exposure).

How to Choose the Right Coated Gloves?

- Assess Hazards: For oils/chemicals → nitrile coated gloves or rubber coated gloves; for precision → pu coated gloves; for general use → latex coated gloves.

- Grip Needs: Wet/oily surfaces → firm grip nitrile coated gloves; dry precision tasks → palm coated gloves (PU).

- Comfort & Durability: Opt for 13-gauge liners (breathable, durable) and reinforced coatings for long shifts.

- Allergy Considerations: Avoid latex if your team has allergies—choose PU, nitrile, or rubber coated alternatives.

HORBEST Coated Work Gloves: Engineered for Industrial Excellence

- PU Coated Gloves: Polyurethane palm coating, 13-gauge nylon liner, dexterous design for precision tasks.

- Nitrile Coated Work Gloves: Reinforced nitrile coating, wear resistance ≥10,000rad, oil/chemical resistance—outperforming maxiflex ultimate gloves nitrile coated in heavy-duty use.

- Rubber Coated Gloves: Heavy-duty rubber coating, chemical/water resistance, breathable liner for comfort.

- Latex Coated Work Gloves: Elastic latex coating, superior grip, ideal for light industrial tasks.

Read Our Reviews: What Customers Say

- “HORBEST’s nitrile coated work gloves have replaced our Maxiflex gloves—better grip in oil, and they last twice as long!” – Automotive Repair Manager

- “The pu coated gloves are perfect for our electronic assembly line—dexterous enough to handle small parts, yet durable enough for daily use.” – Electronics Manufacturer

- “Our chemical handlers swear by the rubber coated gloves—no leaks, no discomfort, even during 10-hour shifts.” – Chemical Plant Safety Supervisor

Understanding Coated Work Gloves: When and What to Use

In industrial, construction, gardening, and cleanroom environments, protecting hands is essential. Coated work gloves are widely used to improve grip, durability, and chemical or abrasion resistance. But with various types—rubber-coated, PU-coated, latex-coated—it’s important to know when and which to choose. This article answers common questions about coated gloves and explains the glove manufacturing process.

When Should You Wear Rubber Coated Gloves?

Rubber coated gloves are ideal for tasks that require:

High grip strength in wet or oily environments.

Resistance to abrasions, cuts, and punctures.

Protection from water or mild chemicals.

Common uses include:

Construction and masonry

Landscaping and gardening

Heavy-duty material handling

General-purpose warehouse work

OSHA Guidelines: According to OSHA, rubber-coated gloves should be worn when working with rough surfaces, sharp edges, or potential chemical splash hazards, but they are not recommended for working with strong solvents or heat sources.

What Are PU (Polyurethane) Coated Gloves?

PU coated gloves have a polyurethane coating, usually on the palm or fingertips. They are:

Lightweight and flexible

Highly breathable, reducing sweat

Perfect for precision tasks

Applications include:

Electronics assembly

Small parts handling

Cleanroom environments

Inspection tasks

These gloves offer excellent tactile sensitivity, making them a popular choice in industries where control and dexterity matter more than heavy protection.

What Are Latex Coated Gloves?

Latex coated gloves feature a natural rubber coating that is:

Durable and elastic

Highly resistant to tears and punctures

Grippy in dry and slightly wet environments

Best suited for:

Construction

Tile or brick laying

Agriculture and yard work

Note: Latex can cause allergic reactions in some users, so alternatives like nitrile or PU-coated gloves may be required in sensitive workplaces.

What Are Polyurethane Coated Gloves?

Polyurethane coated gloves, also known as PU gloves, are designed for delicate, controlled environments. They are made with a polyester or nylon liner and have a thin polyurethane coating that provides:

Excellent abrasion resistance

Minimal lint and contamination

Superior comfort for long wear

These gloves are commonly used in:

Semiconductor and PCB assembly

Automotive and aerospace industries

Quality control and packaging

What Are Coated Work Gloves?

Coated work gloves are fabric gloves (typically cotton, nylon, or polyester) with an added protective coating on the palm, fingers, or entire surface. Coating materials include:

Latex

Nitrile

PU (Polyurethane)

PVC

Each coating offers unique protection properties—some more chemical-resistant, others more abrasion-resistant. The choice depends on the job requirements.

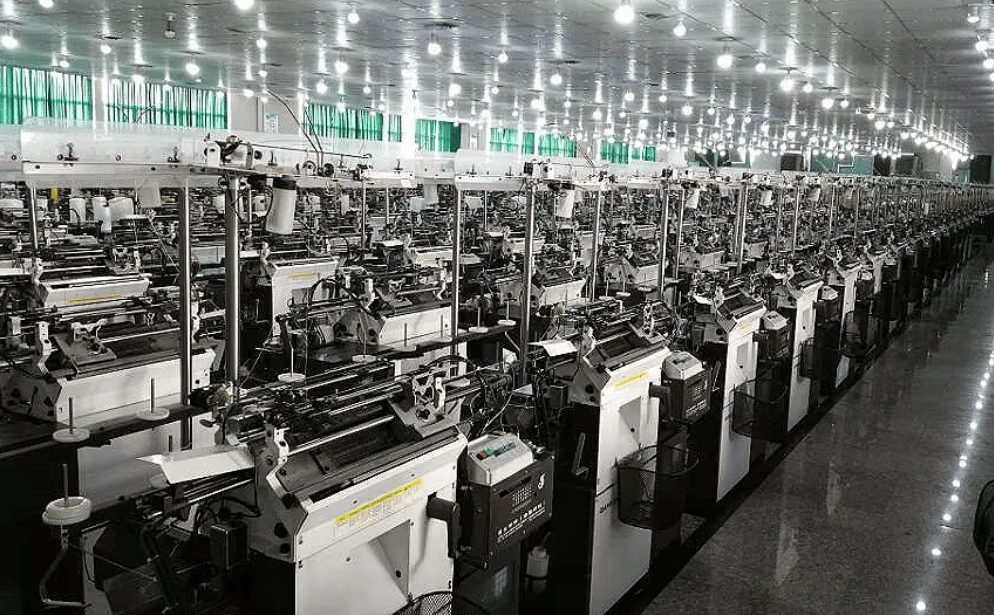

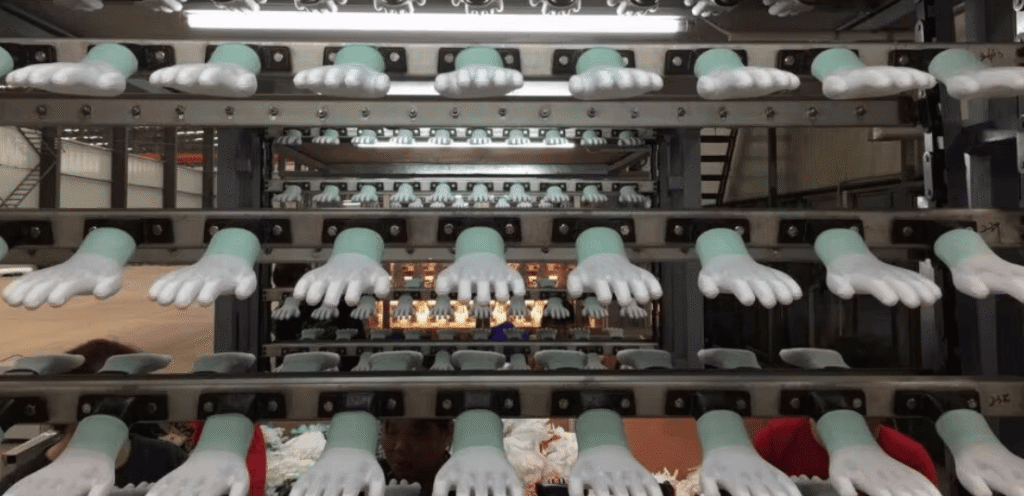

Glove Manufacturing Process Overview

Liner Knitting: A seamless liner is knitted using materials like nylon, cotton, or HPPE.

Cleaning and Drying: The liner is washed and dried to remove impurities.

Coating: Gloves are dipped or sprayed with latex, nitrile, PU, or PVC.

Curing: Coated gloves are cured at high temperatures to solidify the coating.

Quality Inspection: Gloves are checked for defects, coating thickness, flexibility, and fit.

Packaging: Gloves are folded, labeled, and boxed according to size and usage type.

Choosing the right coated glove depends on your specific work environment, risk factors, and the comfort level required. PU gloves offer flexibility and precision, latex gloves provide toughness and grip, while rubber-coated gloves are versatile for general labor. Understanding their differences helps ensure safety, efficiency, and user satisfaction on the job.

For more advice or bulk orders, contact us and explore our full range of coated gloves tailored to your needs.

How to Choose Coated Gloves ?

1. Determine Your Application Needs

Consider the primary use of the gloves:

For ESD-sensitive environments: Choose PU-coated ESD gloves with carbon fiber for excellent conductivity.

For mechanical or warehouse work: Use latex or nitrile coated gloves with superior grip and abrasion resistance.

For wet or oily environments: Opt for nitrile-coated gloves, known for oil resistance and durability.

For lightweight tasks and flexibility: PU-coated gloves offer superior dexterity and comfort.

2. Select the Right Coating

Each coating serves a specific purpose:

Polyurethane (PU): Lightweight, breathable, anti-slip; ideal for precision work.

Latex: Flexible, strong grip in dry environments; good for construction or landscaping.

Nitrile: Oil, grease, and chemical resistant; great for automotive or mechanical industries.

Rubber coating: General use; provides protection against light abrasions and cuts.

3. Consider Glove Fit and Comfort

Proper fit ensures productivity and hand protection. HORBEST gloves come in multiple sizes (S–XL) and feature elastic cuffs and seamless liners for maximum comfort during extended wear.

4. Evaluate Durability and Standards

Choose gloves that meet industry certifications like:

EN388 for mechanical resistance

REACH & RoHS for safety and sustainability

IEC-61340-5-1 for electrostatic protection (for ESD gloves)

✅ Why Choose HORBEST Coated Gloves?

Decades of Expertise: Established in 1996 with full in-house glove manufacturing capabilities.

Premium Materials: Use of top-grade PU, nitrile, latex, and carbon fiber for enhanced performance.

Certified Quality: All gloves meet international standards (CE, EN388, IEC 61340, RoHS, REACH).

Wide Range: From PU fingertip gloves for electronics to latex-coated grip gloves for construction, we’ve got it all.

Custom Solutions: OEM and bulk orders supported, with branding and packaging options.

📞 Contact Us

Need help choosing the right coated gloves?

Email: sales2@esdbest.com

Phone: +86 137 1427 2599