A9 Cut Resistant Gloves

Choosing the best cut resistant gloves means protection, comfort, and functionality. Whether you need a9 cut resistant gloves or Level 5+ gloves for extreme cut risk, HORBEST and KLASS brands offer high-performance gloves tailored to your specific tasks. Ensure your team is properly protected—safety begins with the right gloves.

Ready to protect your hands with confidence? Contact us today for bulk quotes or samples.

| Glove Size | Palm Circumference | Hand Length |

|---|---|---|

| Size 8 (M) | 203mm | 182mm |

| Size 9 (L) | 229mm | 192mm |

| Size 10 (XL) | 254mm | 204mm |

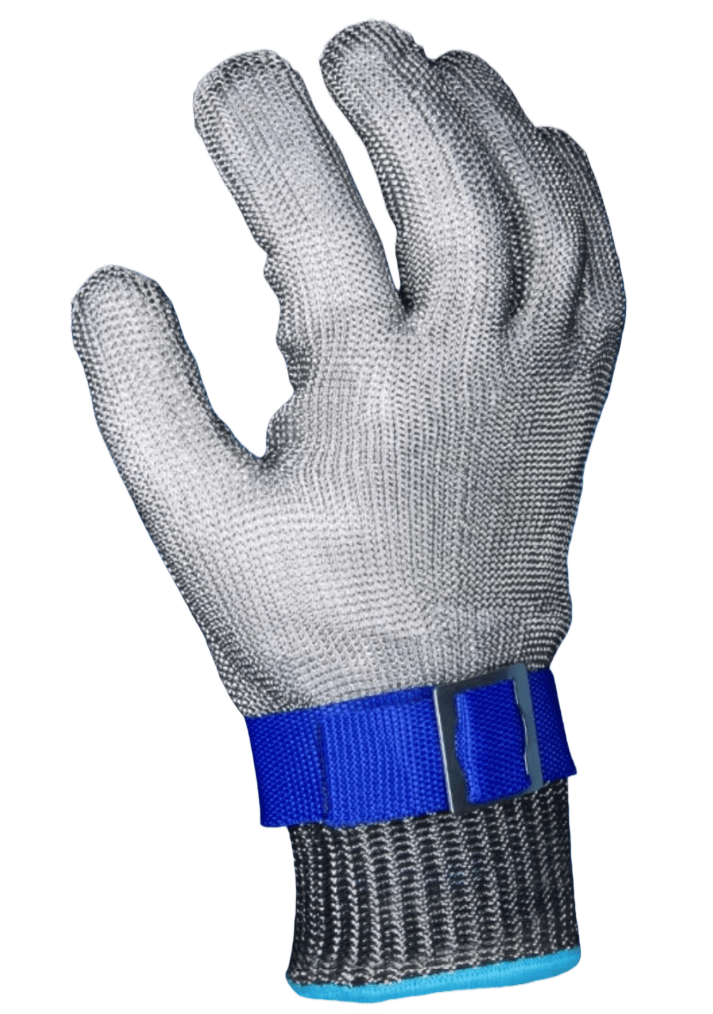

HORBEST A9 Cut Resistant Gloves: The Ultimate Hand Protection for High-Risk Tasks

What Makes A9 Cut Resistant Gloves Unique?

Why HORBEST A9 Cut Resistant Gloves Stand Out

- Premium, Durable Materials: Crafted from a blend of ultra-high-molecular-weight polyethylene (HPPE) fibers (10x stronger than steel by weight), DuPont™ Kevlar® aramid fibers, and food-grade 316 stainless steel wire. This combination delivers not just A9 cut resistance, but also puncture, tear, and abrasion protection.

- Functional Comfort: Unlike bulky, restrictive cut-resistant gloves, HORBEST a9 cut resistant gloves feature an ergonomic, form-fitting design. A textured nitrile coating boosts grip on wet/oily surfaces, while breathable fabric and an adjustable wrist strap ensure all-day comfort—even during precise tasks like deboning meat or assembling small metal parts.

- Multi-Standard Compliance: These gloves meet EN 388 (mechanical risk protection) for all-around durability and FDA 21 CFR 177.2800 (food contact safety)—making them safe for both industrial settings and commercial/home kitchens.

Who Needs HORBEST A9 Cut Resistant Gloves?

- Industrial Workers: Metal fabricators, glass handlers, and construction teams rely on them to avoid cuts from sheet metal, broken debris, or power tool blades.

- Food Professionals: Butchers, slaughterhouse staff, and chefs use them to safely process meat, fish, and poultry—no more worrying about accidental knife slips.

- Emergency Responders: Firefighters and rescue teams depend on their puncture resistance when navigating debris-strewn disaster zones.

Invest in Safety: Choose HORBEST A9 Cut Resistant Gloves

Best Cut Resistant Gloves: A Complete Guide

Cut resistant gloves are essential safety gear designed to protect hands from sharp objects, blades, and cutting tools. Whether you’re in construction, manufacturing, food processing, or metal handling, investing in the best cut resistant gloves ensures both safety and efficiency in high-risk tasks.

What Are Cut Resistant Gloves?

Cut resistant gloves are specially engineered with high-strength fibers such as HPPE (High-Performance Polyethylene), Kevlar, glass fiber, or stainless steel wire. These materials prevent lacerations and minimize the risk of injury caused by accidental cuts during manual operations.

Manufacturing Process

Yarn Composition: Most gloves are made with a blend of HPPE, nylon, spandex, or Kevlar yarns.

Knitting: Gloves are knitted in seamless 13-gauge, 15-gauge, or 18-gauge depending on flexibility and thickness.

Coating Options:

PU (Polyurethane): For dry grip and flexibility.

Nitrile: Offers oil and water resistance.

Latex: Ideal for improved durability and tear resistance.

Quality Testing: Gloves undergo ANSI/ISEA 105 or EN388 standard tests to determine their cut level (A1 to A9 in ANSI; Level 1 to F in EN388).

Key Features and Benefits

✅ High Cut Protection: Engineered to withstand blade cuts and sharp edges.

✅ Comfortable Fit: Seamless design and breathable liners for extended wear.

✅ Excellent Grip: Coated palms provide enhanced grip in wet, dry, or oily conditions.

✅ Durability: Reinforced materials ensure longer lifespan, reducing replacement costs.

✅ Flexible and Lightweight: Maintains hand dexterity for precision work.

Who Can Use the HORBEST Cut Resistant Gloves?

KLASS Cut Resistant Gloves are ideal for:

🔧 Automotive Technicians – Handling sharp tools and sheet metal.

🛠 Construction Workers – Cutting insulation, cables, or drywall.

🍖 Butchers & Food Handlers – Meat cutting and filleting.

🧰 Glass & Metal Workers – Protecting against shards and splinters.

📦 Warehouse Staff – Cutting boxes, straps, and packaging materials.

What Is the Benefit of Cut Resistant Gloves?

🛡 Injury Prevention: Minimize downtime and medical expenses caused by hand injuries.

💼 Compliance: Meet workplace safety standards (ANSI/EN388).

💪 Enhanced Productivity: Workers feel more secure and confident.

🔄 Reusable & Cost-Effective: Long-lasting performance reduces operational costs.

Conclusion

Choosing the best cut resistant gloves means balancing protection, comfort, and functionality. Whether you need Level 3 gloves for light-duty work or Level 5+ gloves for extreme cut risk, HORBEST and KLASS brands offer high-performance gloves tailored to your specific tasks. Ensure your team is properly protected—safety begins with the right gloves.

Ready to protect your hands with confidence? Contact us today for bulk quotes or samples.

📧 Email: sales2@esdbest.com

📞 Phone: +86 137 1427 2599