Product Name | ESD Finger Cots |

Material | Latex |

Features | Non-slip,safety protection |

Package | 1000pcs/1440pcs or customsized |

ESD Finger Cots: The Invisible Guardian of Static-Sensitive Industries

In static-sensitive fields such as semiconductor manufacturing, optoelectronic component assembly, and precision electronic testing, even a tiny electrostatic discharge (

ESD) of only a few hundred volts can damage delicate chips, disrupt circuit signals, or render high-value components useless. As a core part of the personal electrostatic protection system,

ESD Finger Cots (Anti-Static Finger Cots) play an irreplaceable role in isolating fingertip sweat, preventing direct electrostatic transfer, and safely dissipating static charges. Leading brands like HORBEST have elevated ESD Finger Cots from basic protective tools to “precision electrostatic management products” through technological innovation, providing reliable protection for high-end manufacturing.

1 What Are ESD Finger Cots? Core Principles of Anti-Static Protection

ESD Finger Cots are specialized finger protection products designed to suppress electrostatic generation and guide static charge dissipation. Unlike ordinary latex or polyurethane finger cots, their core value lies in controllable electrical conductivity and stable electrostatic performance, which strictly comply with international electrostatic protection standards (such as ANSI/ESD STM11.11 and IEC 61340).

1.1 Anti-Static Mechanism: From “Charge Suppression” to “Safe Dissipation”

The anti-static effect of ESD Finger Cots is achieved through two key designs:

- Conductive Material Blending: High-quality ESD Finger Cots (such as those produced by HORBEST) add conductive fillers (carbon fiber, conductive carbon black, or metal oxide) to the base material (polyurethane, nitrile, or low-protein latex). These fillers form a continuous “conductive path” inside the material, allowing static charges on the fingertip to flow along the path instead of accumulating. The surface resistance is strictly controlled between 10^6 Ω and 10^9 Ω — a range that ensures static is dissipated quickly (avoiding charge buildup) while preventing sudden large-current discharges (which could damage components).

- Grounding Synergy: When used with anti-static wristbands, anti-static shoes, and anti-static workbenches, ESD Finger Cots form a “human-body electrostatic grounding loop”. Static charges on the operator’s body are first transferred to the ESD Finger Cots, then through the wristband to the workbench, and finally to the factory grounding system, achieving “zero-residue” static management. HORBEST’s ESD Finger Cots undergo strict “grounding continuity testing” before leaving the factory, ensuring that the resistance from the cot surface to the grounding point does not exceed 10^9 Ω.

1.2 Key Material Choices: Balancing Protection, Comfort, and Durability

Different base materials of ESD Finger Cots are suitable for different industrial scenarios, and HORBEST has developed targeted material solutions based on scenario needs:

- Polyurethane ESD Finger Cots: The most widely used type, with ultra-thin thickness (0.08-0.12mm) and excellent tactile sensitivity. They are suitable for operations requiring precise control, such as semiconductor wafer handling and IC chip testing. HORBEST’s polyurethane ESD Finger Cots use medical-grade raw materials, which are non-toxic and non-irritating, and can maintain stable anti-static performance even after 5000 times of micro-stretching.

- Nitrile ESD Finger Cots: With strong chemical resistance, they can resist erosion by weak solvents (such as isopropyl alcohol) and oils, making them ideal for electronic component cleaning and soldering scenarios. HORBEST adds anti-aging agents to nitrile materials, extending the service life by 30% compared to ordinary nitrile ESD Finger Cots.

- Low-Protein Latex ESD Finger Cots: Cost-effective and highly elastic, suitable for general electronic assembly (such as PCB plug-in operations). HORBEST uses a special deproteinization process to reduce the protein content to less than 0.05mg/g, minimizing the risk of skin allergies.

2 Core Performance Indicators: How to Define “Qualified” ESD Finger Cots?

The effectiveness of ESD Finger Cots cannot be judged by “feeling” alone; it must meet strict industry standards. HORBEST’s ESD Finger Cots fully comply with global leading standards and pass multi-dimensional performance tests:

2.1 Electrical Performance: The Foundation of Anti-Static Protection

- Surface Resistance: Must be between 10^6 Ω and 10^9 Ω (ANSI/ESD STM11.11 standard). HORBEST uses a high-precision resistance tester (accuracy ±5%) to test each batch of products, with a pass rate of 100%.

- Static Decay Time: The time for 1000V static voltage to decay to 100V on the cot surface must be ≤2 seconds. HORBEST’s test data shows that its ESD Finger Cots can complete the decay in 0.8-1.2 seconds, far exceeding the industry average of 1.5-2 seconds.

- Charging Voltage: When the cot rubs against the component surface (simulating actual operation), the charging voltage must be ≤100V. HORBEST’s ESD Finger Cots have a charging voltage of only 30-50V, effectively avoiding “invisible electrostatic damage” to components.

2.2 Physical and Environmental Adaptability: Ensuring Stability in Harsh Environments

- Tensile Strength: ≥18MPa, ensuring no tearing during frequent finger bending. HORBEST’s ESD Finger Cots undergo a “cyclic stretching test” (stretching to 150% of the original length and recovering 1000 times) without cracking.

- Temperature and Humidity Resistance: They can maintain stable performance in the temperature range of -20℃ to 60℃ and humidity range of 20%RH to 90%RH. This is particularly important for factories in extreme climates (such as high-temperature areas in Southeast Asia or dry areas in Northern China).

- Particulate Emission: In cleanroom scenarios (such as semiconductor Grade 100 cleanrooms), the number of particles ≥0.5μm emitted by ESD Finger Cots must be ≤10 particles per minute. HORBEST’s cleanroom-specific ESD Finger Cots are produced in a Class 1000 clean workshop and undergo laser particle counting testing to meet the strict requirements of high-end manufacturing.

3 Application Scenarios: Where Are ESD Finger Cots Indispensable?

With the development of high-end manufacturing, the application scope of ESD Finger Cots has expanded from traditional electronics factories to more precision fields. HORBEST has launched scenario-specific products for different industries:

3.1 Semiconductor and Integrated Circuit Industry: Zero-Tolerance for Static

In wafer manufacturing (from 4-inch to 12-inch wafers) and chip packaging, even a trace of static can cause “soft breakdown” of the chip (the chip appears normal but fails during use). HORBEST’s ultra-thin polyurethane ESD Finger Cots (thickness 0.08mm) are used here — they fit the fingertips like a second skin, allowing operators to accurately control tweezers to pick up wafers without leaving fingerprints or static marks. At the same time, the cot surface is treated with an anti-adhesive coating to prevent dust or fiber adhesion.

3.2 Optoelectronic Industry: Protecting Light-Sensitive Components

LED chips, OLED screens, and optical lenses are highly sensitive to static. For example, static discharge can cause “dark spots” on OLED screens, making them unusable. HORBEST’s anti-static finger cots for the optoelectronic industry have a “low-light reflection” design — the surface matte treatment reduces light reflection by 40%, avoiding interference with optical testing equipment. In addition, their resistance to isopropyl alcohol ensures that the cots do not deform or lose anti-static performance when cleaning components.

3.3 Medical Electronic Equipment Manufacturing: Balancing Anti-Static and Sterility

Medical devices such as cardiac monitors and ultrasound probes have internal precision circuits that require anti-static protection, while the products themselves require sterility. HORBEST’s medical-grade ESD Finger Cots are sterilized by gamma rays (sterility assurance level SAL 10^-6) and comply with the US FDA 510(k) standard. They are used in the assembly of medical electronic components to prevent static damage and bacterial contamination.

3.4 Aerospace and Military Industry: High Reliability Requirements

The manufacturing of aerospace electronic components (such as satellite communication modules and missile guidance systems) has extremely high requirements for the reliability of ESD protection — the failure of a single component may lead to the failure of the entire mission. HORBEST’s military-grade ESD Finger Cots undergo a “1000-hour accelerated aging test” and can still maintain stable anti-static performance in extreme environments (such as low pressure and high radiation), meeting the military standard MIL-STD-1686.

4 How to Choose and Use ESD Finger Cots Correctly?

Choosing the right ESD Finger Cots and using them properly is the key to maximizing their protective effect. HORBEST provides a complete “selection and use guide” for users:

4.1 Selection Criteria: Match Scenarios, Not Just “Parameters”

- Based on Precision Requirements: For ultra-precise operations (such as wafer handling), choose ultra-thin polyurethane ESD Finger Cots (thickness ≤0.1mm); for general assembly, choose nitrile or latex ESD Finger Cots with better durability.

- Based on Environmental Conditions: In cleanrooms, choose low-particulate ESD Finger Cots (such as HORBEST’s cleanroom series); in environments with chemical contact, choose nitrile ESD Finger Cots with strong chemical resistance.

- Based on User Comfort: For operators who wear cots for a long time (8 hours or more), choose materials with good breathability (such as HORBEST’s polyurethane ESD Finger Cots with micro-porous structure), which can reduce fingertip stuffiness.

4.2 Usage Specifications: Avoid “Invisible Protection Failures”

- Pre-Use Inspection: Before wearing, check whether the ESD Finger Cots have cracks, holes, or foreign objects. At the same time, use an anti-static tester to verify the surface resistance (it is recommended to test once per shift). HORBEST reminds users: if the resistance exceeds 10^9 Ω, the cot must be replaced immediately.

- Correct Wearing Method: Put the cot on from the fingertip, slowly roll it up to the first knuckle, and ensure there are no wrinkles (wrinkles may cause local static accumulation). When removing, roll it down from the root to avoid tearing the cot.

- Avoid Misuse: Do not reuse disposable ESD Finger Cots (reuse will increase the risk of particle shedding and bacterial contamination); do not contact sharp objects (such as needle tips or component edges) to prevent cot damage; do not use oily lubricants (oils will block the conductive path of the cot).

4.3 Matching with Other Anti-Static Equipment

ESD Finger Cots cannot work alone; they need to form a “360° electrostatic protection system” with other equipment:

- Anti-Static Wristband: Ensure that the wristband is in close contact with the skin, and the grounding resistance is between 10^6 Ω and 10^8 Ω.

- Anti-Static Workbench: The workbench surface should be covered with an anti-static mat, and the mat should be reliably grounded.

- Anti-Static Clothing and Shoes: Reduce static generation from the entire body, avoiding “secondary electrostatic transfer” to components.

5 Common Misunderstandings About ESD Finger Cots

In actual use, many users have misunderstandings about ESD Finger Cots, which may lead to reduced protection effects or even component damage. HORBEST clarifies these misunderstandings based on professional experience:

5.1 “As Long as It’s Called ESD Finger Cot, It’s Qualified”

This is a dangerous misunderstanding. Many low-quality ESD Finger Cots on the market only spray a layer of conductive paint on the surface — after a few uses, the paint falls off, and the anti-static performance disappears. HORBEST’s ESD Finger Cots use “integral conductive materials” (conductive fillers are evenly mixed into the base material), ensuring that the anti-static performance remains stable throughout the service life.

5.2 “Thicker ESD Finger Cots Are More Durable and Better”

Thickness and protection effect are not positively correlated. For precision operations (such as IC testing), overly thick ESD Finger Cots (>0.15mm) will reduce tactile sensitivity, leading to operational errors. HORBEST’s ultra-thin polyurethane ESD Finger Cots (0.08mm) balance durability and sensitivity — the tensile strength reaches 20MPa, which is not lower than that of thick cots.

5.3 “ESD Finger Cots Can Replace Anti-Static Wristbands”

Some users believe that wearing ESD Finger Cots is enough to prevent static, so they do not wear anti-static wristbands. In fact, ESD Finger Cots can only dissipate static on the fingertips, while static on other parts of the body (such as the palm and arm) cannot be discharged. HORBEST emphasizes: ESD Finger Cots and anti-static wristbands are complementary, not alternative.

Conclusion

In the era of high-precision manufacturing, ESD Finger Cots have become a “must-have” for static-sensitive industries. As a leader in the anti-static product field, HORBEST has set a high standard for ESD Finger Cots through strict material selection, precise manufacturing processes, and comprehensive performance testing — not only meeting basic anti-static needs but also solving pain points such as poor comfort, short service life, and unstable performance in actual use.

For enterprises, choosing high-quality ESD Finger Cots (such as HORBEST’s products) is not only an investment in component protection but also a guarantee for production efficiency and product quality. For operators, wearing qualified ESD Finger Cots is a “protective shield” for their hands and a “guardian” for the precision components they handle. In the future, with the development of technologies such as 5G, AI, and quantum computing, the demand for ESD protection will become more stringent, and ESD Finger Cots will continue to play a crucial role in the industrial chain.

ESD Latex Finger Cots: Raw Materials and Production Process | HORBEST

HORBEST ESD finger cots are widely used in electronics, precision manufacturing, and medical environments. They are designed to prevent direct finger contact with sensitive components, while offering reliable protection against electrostatic discharge (ESD). Below is a detailed explanation of their raw materials and production process.

I. Raw Materials Composition

HORBEST ESD finger cots are made from premium natural latex, combined with antistatic agents and other functional additives. The key components include:

1. Natural Latex

•The main base material, derived from rubber tree sap. Known for its excellent elasticity, stretchability, and sealing performance, ensuring a snug fit on fingers.

•Latex purity directly affects flexibility and durability, so it must be filtered to remove impurities.

2. Antistatic Agents

•The core functional ingredient. These include ionic types (e.g. quaternary ammonium salts, phosphate esters) and non-ionic types (e.g. polyethylene glycol derivatives).

•These agents lower the surface resistance (typically ≤10¹¹Ω), enabling static electricity to dissipate quickly.

•For high-level ESD environments, conductive fillers like carbon black or metal powders may also be added to enhance conductivity.

3. Other Additives

•Vulcanizing agents (e.g. sulfur): Cross-link rubber molecules to improve strength and aging resistance

•Accelerators (e.g. zinc oxide): Speed up the vulcanization process

•Stabilizers (e.g. antioxidants): Prevent material degradation during storage and processing

•Release agents (e.g. silicone-based): Help finger cots release easily from molds

•Colorants (optional): For different color requirements like natural, blue, or transparent

II. Production Process

The production of HORBEST ESD finger cots uses a dipping molding process, with the following steps:

1. Mold Preparation

•Material: Ceramic or stainless steel molds shaped like a fingertip

•Cleaning: Molds are cleaned with acidic/alkaline solutions or high-pressure water to remove oils or debris

•Release Agent Coating: Silicone-based release agent is applied to ensure smooth demolding

2. Latex Mixing & Maturation

•Mixing: Natural latex, ESD agents, vulcanizers, and additives are blended in mixing tanks (500–1000 rpm) for uniform dispersion

•Maturation: The mixture is left to stand at 25–30°C for 4–8 hours to complete internal reactions and improve latex stability

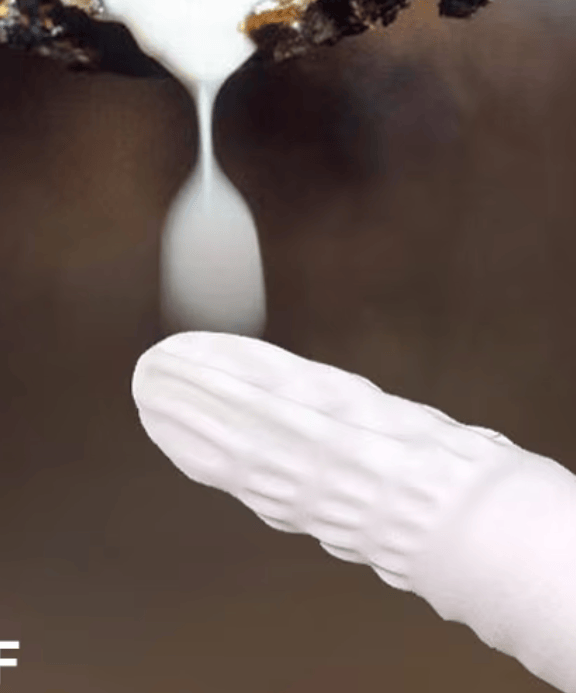

3. Dipping Process

•Molds are dipped vertically into the latex compound. The depth and time (5–15 seconds) determine thickness

•Excess latex drips off for uniform coating

•Optional second dipping for added durability or reinforced fingertips

4. Vulcanization (Curing)

•Heat curing triggers a cross-linking reaction, strengthening elasticity, temperature resistance, and mechanical strength

•Typically baked at 80–120°C for 10–30 minutes, depending on formula

5. Demolding & Trimming

•After cooling, finger cots are mechanically or pneumatically removed from molds

•Edges are trimmed neatly to ensure comfort and usability

6. Washing & Deproteinization (Optional)

•Washed to remove residual chemicals or debris

•For medical-grade products, an enzyme wash is used to remove allergenic proteins in latex

7. ESD Testing & Final Treatment

•Surface resistance is tested using an

ESD meter to ensure compliance with standards (e.g., ANSI/ESD S20.20)

•Defect inspection includes checking for holes, bubbles, and size deviations

•Dried at 40–60°C to avoid mold or moisture damage

8. Packaging & Storage

•Packed in antistatic bags (e.g. 100 pcs per pack), sealed for moisture protection

•Stored in a cool, dry area (≤30°C, ≤60% RH), avoiding sunlight and heat. Shelf life: 1–2 years

9.QC inspection again includes appearance checking, resistance testing, and packaging verification.

III. Key Technical Highlights

•Uniform ESD Performance: Ensuring antistatic agents are evenly dispersed to avoid inconsistent surface resistance

•Precise Thickness Control: Adjusted via latex concentration, dipping time, and mold speed – typically 0.05–0.15 mm

•Optimized Curing: Prevents brittleness or stickiness due to over/under vulcanization

Why Choose HORBEST ESD Finger Cots?

✔ Industry-compliant antistatic protection

✔ Cleanroom-safe and particle-controlled

✔ Ultra-comfortable and snug fit

✔ Available in various colors and weights

✔ Free samples and custom packaging available

Protect your sensitive electronics and ensure

ESD safety with HORBEST ESD finger cots.

Whether you’re in electronics assembly, labs, or cleanrooms, our finger cots deliver dependable performance.

👉 Contact us now for bulk pricing or free samples!

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599