Sticky Mat

Sticky Mat: The Ultimate Solution for Dust and Contamination Control

In environments where cleanliness and contamination control are critical, the sticky mat has become an indispensable tool. Whether used in cleanrooms, laboratories, electronic manufacturing facilities, or construction sites, sticky mat provide a simple, cost-effective way to prevent the spread of dust and particles.

What is a Sticky Mat?

A sticky mat, also known as a tacky mat or cleanroom mat, is a multi-layered mat with an adhesive surface designed to remove dirt and debris from the soles of shoes and wheels before entering a controlled environment. Each mat consists of multiple numbered layers coated with a pressure-sensitive adhesive. Once the top layer becomes dirty, it can be peeled off to reveal a fresh, clean layer underneath.

How Does a Sticky Mat Work?

As people walk over or carts roll across the sticky mat, the adhesive surface captures dust, hair, lint, and other fine particles from footwear or wheels. This significantly reduces the amount of contaminants tracked into clean zones.

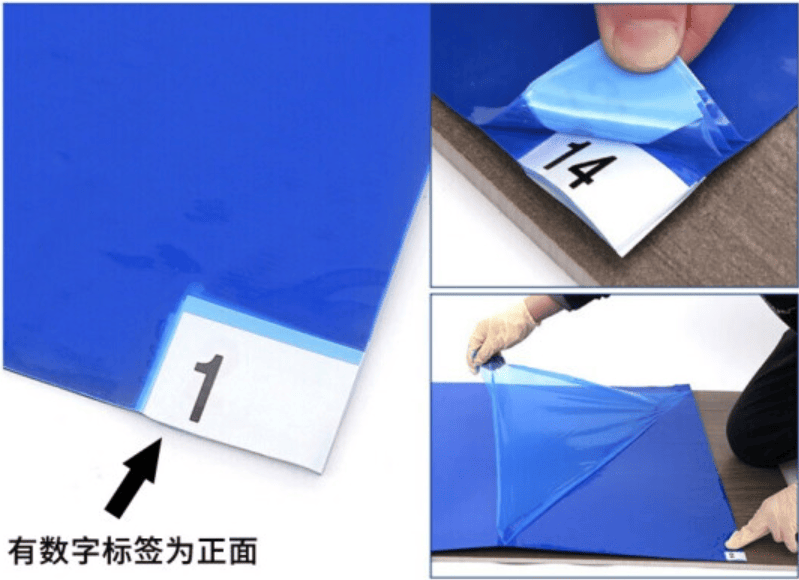

The numbered tabs on each sheet make it easy to peel away a used layer and maintain the mat’s effectiveness. Most sticky mats come in 30-layer or 60-layer versions for extended use.

Key Features of Sticky Mats

•Efficient Contaminant Control: Captures up to 95% of particles from foot traffic.

•Multi-Layer Design: Easy to maintain—just peel off the top layer when it becomes visibly soiled.

•Strong Adhesive: Ensures particles are trapped and not carried forward.

•Easy to Use: Simply place at entryways of cleanrooms, labs, or production areas.

•Custom Sizes and Colors: Available in various dimensions and colors (blue, white, grey) to suit different environments.

Applications of Sticky Mat

Sticky mats are widely used in industries that demand high levels of hygiene and cleanliness, such as:

•Semiconductor and electronics manufacturing

•Pharmaceutical and biotech facilities

•Medical and hospital environments

•Food and beverage production

•Laboratories

•Construction zones entering clean buildings

By placing sticky mats at key transition points, such as doorways, stairwells, and airlocks, facilities can maintain ISO cleanroom standards and reduce contamination-related risks.

Benefits of Using Sticky Mats

•Improved Cleanliness: Maintains floor and air purity by minimizing the transport of particles.

•Reduced Maintenance Costs: Keeps floors and surfaces cleaner for longer, reducing cleaning frequency.

•Enhanced Safety: Reduces risks of foreign particle contamination in sensitive processes.

•Professional Appearance: Gives your facility a cleaner, more controlled aesthetic.

Why Choose Our Sticky Mats?

Our premium-quality sticky mats are manufactured with high-tack adhesives that ensure maximum particulate capture without leaving residue on shoes or wheels. Each mat is individually sealed and numbered for quality assurance, and we offer custom branding and private labeling options for bulk orders.

Sticky Mat – Advanced Dust Control Solution for Clean Environments

Sticky mats, also known as adhesive floor mats or contamination control mats, are an essential part of modern cleanroom and dust-sensitive area management. First developed in South Korea and introduced to China in 1999, particularly in Zhongshan—the hometown of Sun Yat-sen—sticky mats have since become a trusted solution across various industries.

A sticky mat is a multi-layer adhesive mat made using advanced lamination technology and eco-friendly pressure-sensitive water-based adhesive. Each layer is evenly coated with a consistent adhesive surface that ensures strong particle capture without shedding glue, emitting odor, or introducing toxins.

Each sticky mat typically contains 30 numbered adhesive layers (plus 2 protective layers), which can be peeled off one by one when soiled. This makes it easy to maintain a clean surface and effective dust control.

Key Features of Sticky Mats

•Uniform Adhesion: Advanced water-based adhesives provide even tackiness across the entire mat surface.

•Odorless & Non-toxic: Safe for use in sensitive environments.

•Multiple Adhesion Levels: Available in high, medium, and low tack for different needs.

•Easy-to-Peel Layers: Each layer is marked with a numbered tab for convenient replacement.

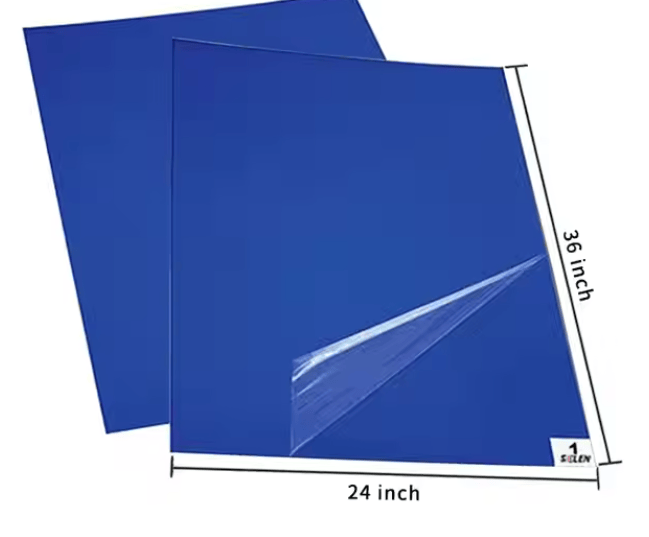

•Custom Sizes & Colors: Common sizes include 26”×45”, 24”×36”, and 18”×36”, available in sky blue, white, and more.

•Environment Compatibility: Operates effectively at temperatures up to 60°C, with an 8-month shelf life.

Structure and Composition

Sticky mats typically feature:

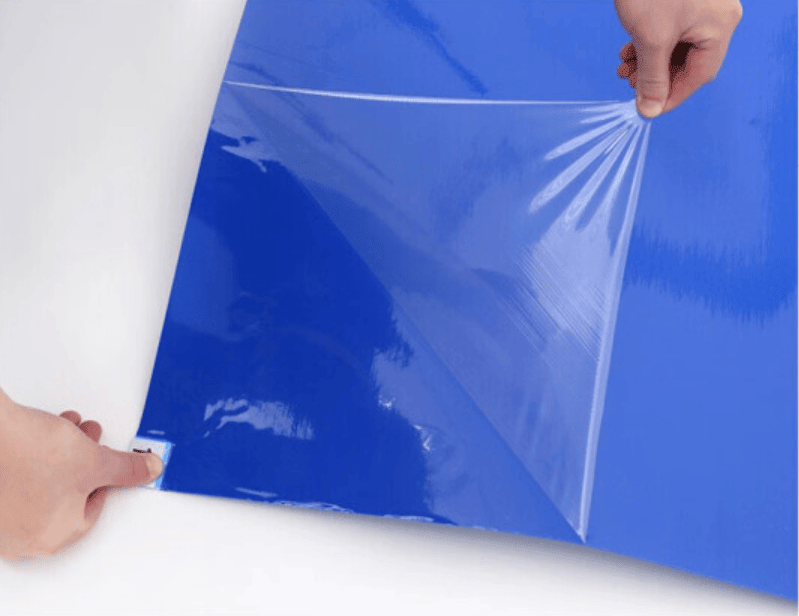

•Top Protective Layer: A transparent non-adhesive PE film.

•Adhesive Layers: 29 layers of PE film, each coated with adhesive and numbered (1–29).

•Bottom Protective Layer: A sky blue double-sided PE adhesive film with the number “30” (or “1”).

Technical Specifications:

Item Specification

Material LDPE + Eco Water-Based Adhesive

Total Thickness 2.00 mm per mat (customizable)

Layer Thickness (avg) 55–63μm

Adhesive Strength (Top Layers) 500g/25mm ±10

Adhesive Strength (Bottom) 600g/25mm ±10

Dust Removal Efficiency 99.9% (within 5 steps)

Temperature Resistance Up to 60°C

Durability Test Up to 8 months

Packaging 8 or 10 mats per carton

Where Are Sticky Mat Used?

Sticky mats are ideal for placement at entry points to cleanrooms, buffer zones, and dust-free environments to prevent particulate transfer from shoes or equipment wheels. Common industries include:

•Semiconductor and electronics manufacturing

•Pharmaceutical production and laboratories

•Medical facilities and hospitals

•Plastic injection molding and printing

•Anti-static zones in power plants

•Food and beverage production environments

By using sticky mat, businesses can prevent cross-contamination, reduce airborne dust, and maintain compliance with hygiene standards.

How to Use a Sticky Mat

1.Installation: Peel off the bottom protective layer and place the mat on a dry, clean floor.

2.Activation: Remove the top protective film to expose the adhesive layer.

3.Maintenance: Once the exposed layer becomes visibly dirty, peel it away to reveal the next clean layer.

4.Layer Indicator: Each sheet is numbered (1–30) for easy tracking.

Performance & Quality Testing

Sticky mats undergo strict testing based on industry standards:

•Tensile Strength: Vertical ≥ 20 MPa; Horizontal ≥ 17 MPa

•Elongation at Break: Vertical ≥ 210%; Horizontal ≥ 255%

•Peel Strength: 180° Peel (GB2792-81): 380g/25mm

•Initial Tack: Loop Tack: 500g/in²

•Holding Power: 1440 minutes

•Aging Resistance: Excellent after 8 months

•Surface Adhesion: Smooth and uniform glue coating

Why Choose Our Sticky Mats?

•Reliable performance in high-demand environments

•High-efficiency dust removal (up to 99.9%)

•Customizable options for size, thickness, tack level, and color

•Easy to install and maintain

•Ideal for both foot traffic and wheeled carts

Choose sticky mat for effective, convenient, and long-lasting dust control. Keep your cleanroom or critical workspace protected—one step at a time.

Conclusion

If your business requires effective dust and contamination control, a sticky mat is a practical and reliable solution. Easy to install, simple to use, and highly efficient—sticky mats protect your workspace and your products.

Invest in clean—invest in sticky mat.

📞 Contact Us Today

For bulk orders, quotes, or product guidance, get in touch with our expert team:

Email: sales2@esdbest.com

Phone: +86 137 1427 2599